(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- MISUMI Việt Nam tham gia Triển lãm Công nghiệp & Sản xuất Việt Nam VIMF Bắc Giang 2025. Xem chi tiết.

MISUMI Vietnam joins VIMF Bac Giang Exhibition 2025. See more. - Vòng Chung kết & Lễ Trao giải cuộc thi Thiết kế Máy tự động hóa 2025. Xem chi tiết.

Final Round & Awarding Ceremony of MISUMI Award 2025. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Belt Width Used(mm)

-

No. of Teeth(T)

-

Pulley Shape

- Shape A

- Shape B

- Shape D

-

Material

- Steel

- Aluminum

- Steel

-

Belt Width(Inch)

-

Surface Treatment

- Not Provided

- Black Oxide Coating

- Clear Anodize

- Black Anodize

- Hard Clear Anodize

- Electroless Nickel Plating

-

Shaft Bore Specifications (Both Ends Stepped Hole) [Y](mm)

-

Shaft Bore Specifications (New JIS Keyway Hole + Tap) [N](Ø)

-

Shaft Bore Specifications (Old JIS Keyway Hole + Tap) [C](mm)

-

Shaft Bore Specifications (Round Hole + Tap) [P](mm)

-

Shaft Bore Specifications (Round Hole) [H](mm)

-

Shaft Bore Specifications (Stepped Hole) [V](mm)

-

Shaft Bore Specifications (Stepped Hole: Counterbored Holes on the Hub Side) [F](mm)

-

Shaft Bore Specifications (Two-stepped Hole) [WB](mm)

-

type

- ATPA□□L

- ATPB□□L

- ATPK□□L

- ATPN□□L

- ATPP□□L

- ATPT□□L

- ATP□□L

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 6 Day(s) or Less

- 8 Day(s) or Less

- 9 Day(s) or Less

- 10 Day(s) or Less

- 13 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Timing Pulleys - L Type (Part Number)

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- Please note that the swaged flange options, NFC, RFC, and LFC, are not reflected in the CAD data.

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

Product Description

[Material]

· Pulley: Extra super duralumin aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC,

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

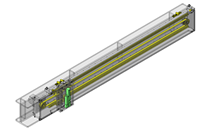

■L type

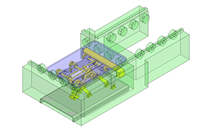

● Pulley Shape

Tooth Profile

(ISO Standard Rack Dimensions)

Shape A

Shape B

Shape D

* H Dimension L050=5, L075=8, L100=11

[ ! ]1

[ ! ]1

[ ! ]2

[ ! ]2

[ ! ]2

[ ! ] For aluminum flanges, the flange thickness is 1.5.

[!] 1 t = 2.0 for 60 and 72 toothed pulleys (Machined Flange)

[ ! ] The tolerance of the tap position dimension from the boss end face and pulley end face is ±0.3.

[ ! ] Shaft Bore Specs. H (Round hole), V or F (Stepped Hole), Y (Both Sides Stepped Hole) and WB (Two-stepped Hole) do not have tapped holes.

[ ! ] Unless otherwise specified except for teeth and F dimensions, the dimension tolerance conforms to JIS B 0405 Class m.

● Shaft Bore Specification

Select shaft bore spec mark and each dim. from the table below.

[ ! ] Surface treatment may not be applied to the shaft bores.

H round hole

P Round Hole + Tap

N New JIS Keyway + Tap

C Old JIS Keyway + Tap

[ ! ] For A-Shape pulley, the screw holes are set at around 120° to keep away from peaks.

[ ! ] Specify NK10 when selecting the shaft bore dia. 10

and the keyway width 4.0 mm.

V Stepped Hole

F Stepped Hole

(Counterbored Hole on the Hub Side)

Y Both Ends Stepped Hole

WB Two-stepped hole

[ ! ] Z - d ≥ 2

[ ! ]3.0 ≤ J ≤ W-3.0

[ ! ] Applicable to Shape B only

[ ! ] Z - d ≥ 2

[ ! ]3.0 ≤ J ≤ L-3.0

[ ! ] Applicable to Shape A only

[ ! ]Q (R)-Y ≥ 2

[ ! ]S+T ≤ W-3.0

[ ! ]S (T) ≥ 3.0

[ ! ] Applicable to Shape A only

[ ! ]Q-R ≥ 2

[ ! ]R-WB ≥ 2

[ ! ]S+T ≤ W-3.0

[ ! ]S (T) ≥ 3.0

(Shaft Bore Specs.: P, N, C)

| dH7 Shaft Bore I.D. | M (Coarse) | Accessory Set Screws |

| 6 to 12 | M4 | M4 × 3 |

| 13 to 17 | M5 | M5 × 4 |

| 18 to 30 | M6 | M6 × 5 |

| 31 to 45 | M8 | M8 × 6 |

| 46 to 70 | M10 | M10 × 8 |

| mm | Nominal | |||

| L050 | L075 | L100 | L150 | |

| A | 14 | 21 | 27 | 40 |

| W | 19 | 26 | 32 | 45 |

| L Number of Teeth 10 to 59 | 31 | 38 | 44 | 57 |

| L Number of Teeth 60, 72 | 39 | 46 | 53 | 57 |

| Type | Belt Width | [M] Material | [S] Surface Treatment | [A] Accessory Set Screws | ||||

| 12.7 mm (1/2 in) | 19.1 mm (3/4 in) | 25.4 mm (1 in) | 38.1 mm (1.5 in) | Pulley | Flange * | |||

| L050 | L075 | L100 | L150 | |||||

| ATPA | ● | ● | ● | ● | Extra Super Duralumin Aluminum alloy | Aluminum alloy | Clear Anodize | SUS304 |

| ATPB | ● | ● | ● | ● | Black Anodize | |||

| ATPK | ● | ● | ● | ● | Hard Clear Anodize | |||

| ATPN | ● | ● | ● | ● | Electroless nickel plating | |||

| ATPT | ● | ● | ● | ● | S45C Equivalent | SPCC | — | SCM435 (Black Oxide) |

| ATP | ● | ● | ● | ● | Black Oxide Coating | |||

| ATPP | ● | ● | ● | ● | Electroless nickel plating | |||

| ATPS | ● | ● | ● | — | SUS304 | SUS304 | — | SUS304 |

* Flange is not included for Shape D.

Specification Table

| Part number | — | Pulley Shape | — | Shaft Bore Specs.: I.D. | — | Z | — | J | — | Q | — | R | — | S | — | T | |

| (Shaft Bore Specs.: H, P, N, C) | ATP14L075 | — | A | — | N10 | R47 | |||||||||||

| (Shaft Bore Specs.: V, F) | ATP36L100 | — | A | — | V15 | — | Z29 | — | J18.0 | ||||||||

| (Shaft Bore Specs.: Y, WB) | ATP50L150 | — | A | — | Y25 | — | Q47 | — | — | S12 | — | T12 |

| Part number | Pulley Shape | Pulley Shape | P.D. | O.D | D | F | E | |||||||

| Type | Number of Teeth | Type Nominal Width | A | B | ||||||||||

| Shaft Bore Specs. | ||||||||||||||

| H Round Hole V·Y·WB Stepped Hole | P Round Hole Tapped | N·C Keyway Tapped | H Round Hole V·F Stepped Hole | P Round Hole Tapped | N·C Keyway Tapped | |||||||||

| d·Z1 mm Increments / Selectable | ||||||||||||||

| Aluminum ATPA ATPB ATPK ATPN Steel ATPT ATP ATPP Stainless Steel ATPS | 10 | L050 | A B | 6-20 | 6-14 | 8-14 | 6-18 | 6-14 | 8-14 | 30.32 | 29.56 | 22 | 36 | 24 |

| 11 | 8-23 | 8-18 | 8-18 | 8-18 | 8-14 | 33.35 | 32.59 | 40 | 27 | |||||

| 12 | L050 L075 | 8-26 | 8-23 | 8-18 | 8-18 | 36.38 | 35.62 | 27 | 45 | 30 | ||||

| 13 | 39.41 | 38.65 | ||||||||||||

| 14 | L050 L075 L100 L150 | 8-31 | 8-23 | 8-21 | 8-26 | 8-20 | 8-20 | 42.45 | 41.68 | 30 | 48 | 35 | ||

| 15 | 8-23 | 45.48 | 44.72 | |||||||||||

| 16 | 10-36 | 10-28 | 10-23 | 10-28 | 10-22 | 10-22 | 48.51 | 47.75 | 32 | 55 | 40 | |||

| 17 | 10-26 | 10-30 | 10-24 | 10-23 | 51.54 | 50.78 | 34 | |||||||

| 18 | 10-41 | 10-33 | 10-34 | 10-32 | 10-26 | 54.57 | 53.81 | 36 | 61 | 45 | ||||

| 19 | 12-46 | 12-34 | 12-35 | 12-34 | 12-28 | 12-25 | 57.61 | 56.84 | 38 | 67 | 50 | |||

| 20 | 12-36 | 12-30 | 12-26 | 60.64 | 59.88 | 40 | ||||||||

| 21 | 12-52 | 12-40 | 12-37 | 12-38 | 63.67 | 62.91 | 42 | 70 | 56 | |||||

| 22 | 12-53 | 12-44 | 12-38 | 12-41 | 12-33 | 12-30 | 66.70 | 65.94 | 45 | 80 | 60 | |||

| 23 | 69.73 | 68.97 | 50 | |||||||||||

| 24 | 12-63 | 12-49 | 12-44 | 12-46 | 12-38 | 72.77 | 72.00 | 87 | 67 | |||||

| 25 | 12-45 | 75.80 | 75.04 | |||||||||||

| 26 | 78.83 | 78.07 | ||||||||||||

| 27 | 81.86 | 81.10 | ||||||||||||

| 28 | 12-71 | 12-57 | 12-50 | 84.89 | 84.13 | 95 | 75 | |||||||

| 29 | 87.93 | 87.17 | ||||||||||||

| 30 | 12-72 | 12-62 | 12-55 | 12-52 | 12-42 | 12-34 | 90.96 | 90.20 | 56 | 99 | 80 | |||

| 31 | 93.99 | 93.23 | ||||||||||||

| 32 | 14-76 | 14-65 | 14-55 | 14-52 | 14-42 | 14-34 | 97.02 | 96.26 | 104 | 84 | ||||

| 33 | 14-83 | 14-70 | 14-59 | 14-49 | 14-41 | 100.05 | 99.29 | 63 | 111 | 90 | ||||

| 34 | 103.08 | 102.32 | ||||||||||||

| 35 | 106.12 | 105.36 | 115 | 95 | ||||||||||

| 36 | 14-85 | 109.15 | 108.39 | 123 | 102 | |||||||||

| 37 | 112.18 | 111.42 | ||||||||||||

| 38 | 15-85 | 15-70 | 15-55 | 15-59 | 15-49 | 15-41 | 115.21 | 114.45 | 127 | 105 | ||||

| 39 | 118.24 | 117.48 | ||||||||||||

| 40 | 121.28 | 120.51 | 131 | 110 | ||||||||||

| 41 | 16-67 | 16-57 | 16-49 | 124.31 | 123.55 | 135 | 115 | |||||||

| 42 | 16-85 | 16-70 | 16-55 | 127.34 | 126.58 | 71 | ||||||||

| 43 | 130.37 | 129.61 | 140 | 120 | ||||||||||

| 44 | 133.40 | 132.64 | ||||||||||||

| 45 | 136.44 | 135.68 | 144 | 125 | ||||||||||

| 46 | 139.47 | 138.71 | ||||||||||||

| 47 | 142.50 | 141.74 | 152 | 130 | ||||||||||

| 48 | 145.53 | 144.77 | ||||||||||||

| 49 | 148.56 | 147.80 | 160 | 140 | ||||||||||

| 50 | 151.60 | 150.83 | ||||||||||||

| Steel ATPT ATP ATPP | 51 | 154.63 | 153.87 | 165 | ||||||||||

| 52 | 157.66 | 156.90 | ||||||||||||

| 53 | 160.69 | 159.93 | 170 | 150 | ||||||||||

| 54 | 163.72 | 162.96 | ||||||||||||

| 55 | 16-90 | 166.75 | 165.99 | 180 | 155 | |||||||||

| 56 | 169.79 | 169.03 | ||||||||||||

| 57 | 16-95 | 172.82 | 172.06 | 160 | ||||||||||

| 58 | 16-100 | 175.85 | 175.09 | 190 | 165 | |||||||||

| 59 | 16-105 | 178.88 | 178.12 | 170 | ||||||||||

| 60 | A D (L150A only) | 181.91 | 181.15 | 170 (160) | ||||||||||

| 72 | 218.30 | 217.53 | 225 | 200 (197) | ||||||||||

| [NG]Shaft Bore Dia. 9, 51-54 are not available for Shaft Bore Spec. N. [!]Shaft Bore Dia.6.35 is selectable for Shaft Bore Specs. H, P, V, and F. [!] NK10 is selectable for Shaft Bore Spec. N. [NG]Shaft Bore Dia. 8, 11, 13, 14, 17, or 21-55 are not available for Shaft Bore Spec. C. | ||||||||||||||

Alterations

| Part number | — | Pulley Shape | — | Shaft Bore Specs.: I.D. | — | Z | — | J | — | Q | — | R | — | S | — | T | — | (KC90, etc.) | ||

| ATP20L075 | — | A | — | H25 | — | KSC36 | — | K5 | ||||||||||||

| Alterations | Set Screw Angle Change | No Flange | Single Flange | Flange Cut |

| Code | KC90 | NFC | RFC·LFC | FC |

| Spec. | Changes an angle of set screw to 90°. [ ! ] For A-Shape pulley, the screw holes are set at around 90° to keep away from peaks.  | (Flange 2 pcs. Included) Ordering Code NFC [NG] Not applicable to Shape D  | (Flange 1 pc. Included) Ordering Code RFC Application Notes [NG] Not applicable to Shape D  | Cut the flange O.D. in 0.5 mm increments. Ordering Code FC17 Application Notes [ ! ]FC ≥ (O. D.) +1 [ ! ]FC ≤ F-2 [ ! ] No surface treatment is applied on flange circumference. [NG] Not applicable to Shape D  |

| Alterations | Retaining Ring Groove | Taper for Bearing Holder | Hub Shortening | Tapped Hole Dimensions | Included Set Screw Length Change | ||||||||||||||||||||||||

| Code | SRG | BTC | BC | TPC | SLH | ||||||||||||||||||||||||

| Spec. | Retaining Ring Groove applicable to the shaft dia. of stepped hole is machined. Ordering Code 2.5 to 36.5 mm 0.5 mm Increments Applicable Conditions [ ! ] Minimum Thickness: 2 mm [ ! ] Applicable to Shaft Bore Specs. V and F only [ ! ] Standards of retaining ring groove for Z dim. is applied [ ! ] n ≤ J−SRG−mOrdering Code SRG7  | Taper for retaining bearing inner ring Ordering Code BTC8-TL1.5 Application Notes [ ! ] Applicable to Shape A only [ ! ] Applicable to Shaft Bore Specs. H and P only [ ! ]TL < L-W [ ! ] When E-D ≤ 6, one side installed and 1 pc. of flange included  | Cuts the hub length in 0.5 mm increments. Ordering Code BC6.5 Application Notes [!] Shaft Bore Specs. H, V, F: 3 ≤ BC < L-W [!] Shaft Bore Specs. P, N, C: M+3 ≤ BC < L-W [NG] Not applicable to Shape A and D | Ordering Code TPC5 Application Notes [ ! ] Applicable to Shaft Bore Specs. P, N, C only

| Ordering Code SLH10 Application Notes [ ! ] Applicable to Shaft Bore Specs. P, N, C only

|

| Alterations | Add Side Holes [!] Conditions may vary depending on the shaft bore specs. | ||

| Side Tapped Hole | Side Through Hole | Side Counterbored | |

| Code | QTC·QFC·QSC | KTC·KFC·KSC | ZTC·ZFC·ZSC |

| Spec. | Machines tapped hole on the side surface of hub side. Ordering Code QTC28−M4 Q□C Selection Specify the hole position (P. C. D. dim.). M Selection M3, M4, M5, M6, M8 Application Notes [NG] Not applicable to Shape D [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) | Machines through hole on the side surface. Ordering Code KTC28−K4.5 K□C Selection Specify the hole position (P. C. D. dim.). Specify K K4.0 to 13.0 (0.5 mm Increments) Application Notes [NG] Not applicable to Shape D [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) | Machines counterbored hole on the side surface. Ordering Code ZTC28−ZM4 Z□C Selection Specify the hole position (P. C. D. dim.). ZM Selection ZM3, ZM4, ZM5, ZM6, ZM8 Application Notes [NG] Not applicable to Shape D [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| ATP14L100-A-P[8-21/1] |

| ATP14L100-A-V[8-25/1] |

| ATP14L100-A-Y[8-25/1] |

| ATP14L100-B-C[10,12,15,16,18,19,20] |

| ATP14L100-B-F[8-24/1] |

| ATP14L100-B-H[8-26/1] |

| ATP14L100-B-N8 |

| ATP14L100-B-N[10-20/1] |

| ATP14L100-B-NK10 |

| ATP14L100-B-P[8-20/1] |

| ATP14L100-B-V[8-24/1] |

| ATP14L150-A-C[10,12,15,16,18,19,20] |

| ATP14L150-A-H[8-27/1] |

| ATP14L150-A-N8 |

| ATP14L150-A-N[10-21/1] |

| ATP14L150-A-NK10 |

| ATP14L150-A-P[8-21/1] |

| ATP14L150-A-V[8-25/1] |

| ATP14L150-A-Y[8-25/1] |

| ATP14L150-B-C[10,12,15,16,18,19,20] |

| ATP14L150-B-F[8-24/1] |

| ATP14L150-B-H[8-26/1] |

| ATP14L150-B-N8 |

| ATP14L150-B-N[10-20/1] |

| ATP14L150-B-NK10 |

| ATP14L150-B-P[8-20/1] |

| ATP14L150-B-V[8-24/1] |

| ATP15L050-A-C[10,12,15,16,18,19,20] |

| ATP15L050-A-H[8-27/1] |

| ATP15L050-A-N8 |

| ATP15L050-A-N[10-23/1] |

| ATP15L050-A-NK10 |

| ATP15L050-A-P[8-23/1] |

| ATP15L050-A-V[8-25/1] |

| ATP15L050-A-Y[8-25/1] |

| ATP15L050-B-C[10,12,15,16,18,19,20] |

| ATP15L050-B-F[8-24/1] |

| ATP15L050-B-H[8-26/1] |

| ATP15L050-B-N8 |

| ATP15L050-B-N[10-20/1] |

| ATP15L050-B-NK10 |

| ATP15L050-B-P[8-20/1] |

| ATP15L050-B-V[8-24/1] |

| ATP15L075-A-C[10,12,15,16,18,19,20] |

| ATP15L075-A-H[8-27/1] |

| ATP15L075-A-N8 |

| ATP15L075-A-N[10-23/1] |

| ATP15L075-A-NK10 |

| ATP15L075-A-P[8-23/1] |

| ATP15L075-A-V[8-25/1] |

| ATP15L075-A-Y[8-25/1] |

| ATP15L075-B-C[10,12,15,16,18,19,20] |

| ATP15L075-B-F[8-24/1] |

| ATP15L075-B-H[8-26/1] |

| ATP15L075-B-N8 |

| ATP15L075-B-N[10-20/1] |

| ATP15L075-B-NK10 |

| ATP15L075-B-P[8-20/1] |

| ATP15L075-B-V[8-24/1] |

| ATP15L100-A-C[10,12,15,16,18,19,20] |

| ATP15L100-A-H[8-27/1] |

| ATP15L100-A-N8 |

| ATP15L100-A-N[10-23/1] |

| ATP15L100-A-NK10 |

| ATP15L100-A-P[8-23/1] |

| ATP15L100-A-V[8-25/1] |

| ATP15L100-A-Y[8-25/1] |

| ATP15L100-B-C[10,12,15,16,18,19,20] |

| ATP15L100-B-F[8-24/1] |

| ATP15L100-B-H[8-26/1] |

| ATP15L100-B-N8 |

| ATP15L100-B-N[10-20/1] |

| ATP15L100-B-NK10 |

| ATP15L100-B-P[8-20/1] |

| ATP15L100-B-V[8-24/1] |

| ATP15L150-A-C[10,12,15,16,18,19,20] |

| ATP15L150-A-H[8-27/1] |

| ATP15L150-A-N8 |

| ATP15L150-A-N[10-23/1] |

| ATP15L150-A-NK10 |

| ATP15L150-A-P[8-23/1] |

| ATP15L150-A-V[8-25/1] |

| ATP15L150-A-Y[8-25/1] |

| ATP15L150-B-C[10,12,15,16,18,19,20] |

| ATP15L150-B-F[8-24/1] |

| ATP15L150-B-H[8-26/1] |

| ATP15L150-B-N8 |

| ATP15L150-B-N[10-20/1] |

| ATP15L150-B-NK10 |

| ATP15L150-B-P[8-20/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | RoHS | Belt Width Used (mm) | No. of Teeth (T) | Pulley Shape | Material | Belt Width (Inch) | Surface Treatment | Shaft Bore Specifications (Both Ends Stepped Hole) [Y] (mm) | Shaft Bore Specifications (New JIS Keyway Hole + Tap) [N] (Ø) | Shaft Bore Specifications (Old JIS Keyway Hole + Tap) [C] (mm) | Shaft Bore Specifications (Round Hole + Tap) [P] (mm) | Shaft Bore Specifications (Round Hole) [H] (mm) | Shaft Bore Specifications (Stepped Hole) [V] (mm) | Shaft Bore Specifications (Stepped Hole: Counterbored Holes on the Hub Side) [F] (mm) | Shaft Bore Specifications (Two-stepped Hole) [WB] (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | 8 ~ 21 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | - | 8 ~ 25 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | 8 ~ 25 | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | - | - | 8 ~ 24 | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | 8 ~ 26 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | 10 ~ 20 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | 8 ~ 20 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 14 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | - | 8 ~ 24 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | 8 ~ 27 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 10 ~ 21 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | 8 ~ 21 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | - | 8 ~ 25 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | 8 ~ 25 | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | - | - | 8 ~ 24 | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | 8 ~ 26 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 10 ~ 20 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | 8 ~ 20 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 14 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | - | 8 ~ 24 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | - | 8 ~ 27 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | 10 ~ 23 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | 8 ~ 23 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | - | - | 8 ~ 25 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape A | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | 8 ~ 25 | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | - | - | - | 8 ~ 24 | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | - | 8 ~ 26 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | 10 ~ 20 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | 8 ~ 20 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 12.7 | 15 | Shape B | [Steel] S45C Equivalent | 0.5 | Black Oxide Coating | - | - | - | - | - | 8 ~ 24 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | - | 8 ~ 27 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | 10 ~ 23 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | 8 ~ 23 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | - | - | 8 ~ 25 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape A | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | 8 ~ 25 | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | - | - | - | 8 ~ 24 | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | - | 8 ~ 26 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | 10 ~ 20 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | 8 ~ 20 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 19.1 | 15 | Shape B | [Steel] S45C Equivalent | 0.75 | Black Oxide Coating | - | - | - | - | - | 8 ~ 24 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | 8 ~ 27 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | 10 ~ 23 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | 8 ~ 23 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | - | 8 ~ 25 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape A | [Steel] S45C Equivalent | 1 | Black Oxide Coating | 8 ~ 25 | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | - | - | 8 ~ 24 | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | 8 ~ 26 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | 10 ~ 20 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | 8 ~ 20 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 25.4 | 15 | Shape B | [Steel] S45C Equivalent | 1 | Black Oxide Coating | - | - | - | - | - | 8 ~ 24 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | 8 ~ 27 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 10 ~ 23 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | 8 ~ 23 | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | - | 8 ~ 25 | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape A | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | 8 ~ 25 | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | 10 ~ 20 | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | - | - | 8 ~ 24 | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | - | 8 ~ 26 | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 8 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | 10 ~ 20 | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | NK10 (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm) | - | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 38.1 | 15 | Shape B | [Steel] S45C Equivalent | 1.5 | Black Oxide Coating | - | - | - | 8 ~ 20 | - | - | - | - |

| Part Number |

|---|

Loading...Tải…

Basic InformationThông tin cơ bản

| Type | Timing Pulleys | Belt Type | L | Timing Pulley / Idler | Pulleys |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy