(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Thông báo: Cập nhật hệ thống Hải quan và Thuế có thể gây chậm trễ trong giao hàng. Xem chi tiết.

- Thể lệ và Giải thưởng cuộc thi "Thiết kế máy Tự động hóa 2025" do MISUMI Việt Nam tổ chức. Xem chi tiết.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Basic Shape

-

Large Head

Large Head -

Straight

Straight

-

-

Insertion Guide Tip Shape

-

Round

Round -

Diamond

Diamond

-

-

Insertion Guide Tip Type

-

Tapered

Tapered -

Taper R

Taper R -

R

R

-

-

Surface Treatment

- Not Provided

- Black Oxide

- Hard Chrome Plating

-

Heat Treatment

- Not Provided

- Dip Quenching

-

Material

- Steel

- Stainless Steel

- Steel

-

Locating Side Outer Dia. P (Ø)(mm)

-

Mounting Side Outer Dia. D(mm)

-

Mounting Side Tolerance

-

Screw Dia. M(mm)

-

Mounting Section Length L(mm)

-

G(mm)

-

Length of Locating Side B(mm)

-

R(mm)

-

type

- LPCA

- LPCB

- LPCBA

- LPCBB

- LPCBC

- LPCC

- LPCCA

- LPCCB

- LPCCC

- LPCDA

- LPCDB

- LPCDC

- LPCGA

- LPCGB

- LPCGC

- LPCJA

- LPCJB

- LPCJC

- LPCRA

- LPCRB

- LPCRC

- LPCSA

- LPCSB

- LPCSC

- LPDGA

- LPDGB

- LPDGBA

- LPDGBB

- LPDGBC

- LPDGC

- LPDGCA

- LPDGCB

- LPDGCC

- LPDGGA

- LPDGGB

- LPDGGC

- LPDGJA

- LPDGJB

- LPDGJC

- LPDGRA

- LPDGRB

- LPDGRC

- LPDGSA

- LPDGSB

- LPDGSC

- LPGA

- LPGB

- LPGBA

- LPGBB

- LPGBC

- LPGC

- LPGCA

- LPGCB

- LPGCC

- LPGDA

- LPGDB

- LPGDC

- LPGGA

- LPGGB

- LPGGC

- LPGJA

- LPGJB

- LPGJC

- LPGRA

- LPGRB

- LPGRC

- LPGSA

- LPGSB

- LPGSC

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 2 Day(s) or Less

- 3 Day(s) or Less

- 4 Day(s) or Less

- 9 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Locating Pins - Tip Shape Selectable (Straight Tapped)

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

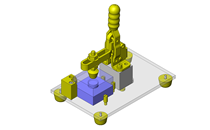

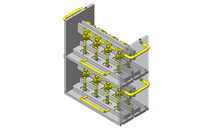

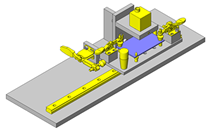

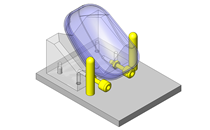

Product Description

- Locating Pins - Tip Shape Selectable (Straight Tapped) from MISUMI.

- The tip shape is selectable from three types. To be mounted from back using bolts. Improved maintainability compared to the press fit type.

- The material of locating pin can be selected 4 types, S45C Equivalent, steel SKS3 Equivalent, stainless steel SUS304, SUS440C or 13Cr stainless.

- SUS440C or 13Cr stainless of round type and diamond type has an identification groove at any position on D part.

- The tightening torque (ref. value) for hardened products is strength class 8.8. Not applicable when using locking materials or lock washers.

d = D - 0.2 [ ! ] Relief dimensions are reference values.

[ ! ] SUS304 products may not be polished and have no centering hole.

[ ! ] SUS440C or 13Cr Stainless Steel of Round and Diamond Types has an identification groove at any position on D part.

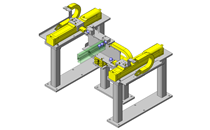

| Tip Shape | ||||

| A Config. | [ ! ]R ≥ P/2

| |||

| B Config. | [ ! ]G ≤ P  [!] ℓ2 = PG 2tan30° Reference: 2tan30° ≒ 1.15 [ ! ]When G = P, add about C0.2 chamfering | |||

| C Config. | [ ! ]R ≤ P/2 [!] ℓ3 = P 2 ÷ tan30° + R − (R ÷ sin30°) [!] Reference: tan30° ≒ 0.577, sin30° = 0.5 | |||

| Material No. | [M] Material | [S] Surface Treatment | [H] Hardness | Round | Diamond | Straight |

| (1) | SKS3 Equivalent | — | Treated Hardness: 55 to 60 HRC | LPGJ | LPDGJ | LPCJ |

| (2) | SKS3 Equivalent | Hard Chrome Plating | Treaded Hardness: 50 to 55 HRC Plating Hardness: 750 HV or more | LPGG | LPDGG | LPCG |

| (3) | S45C Equivalent | — | Treated Hardness: 45 to 50 HRC | LPG | LPDG | LPC |

| (4) | S45C Equivalent | Black Oxide | Treated Hardness: 45 to 50 HRC | LPGB | LPDGB | LPCB |

| (5) | S45C Equivalent | Hard Chrome Plating | Treated Hardness: 45 to 50 HRC Plating Hardness: 750 HV or more | LPGR | LPDGR | LPCR |

| (6) | SUS304 | — | — | LPGS | LPDGS | LPCS |

| (7) | SUS304 | Hard Chrome Plating | Plating Hardness: 750 HV or more | LPGD | — | LPCD |

| (8) | SUS440C or 13Cr Stainless Steel | — | Treaded Hardness: 50 to 55 HRC | LPGC | LPDGC | LPCC |

Specification Table

| Part Number | — | P | — | B | — | R | — | G | — | L |

| LPGA6 LPGB10 LPCA6 | — — — | P10.0 P16.0 P10.0 | — — — | B25.0 B50.0 B25.0 | — — | R6 R6 | — | G13 | — — | L6 L16 |

| Part Number | P 0.01 mm Increments | B 0.1 mm Increments | R 1 mm Increments | G 1 mm Increments | L 1 mm Increments | M (Coarse) | * Tightening Torque N・cm | (W) | ||||

| Type | Tip Config. | D | D Dimension Tolerance g6 | |||||||||

| Shape A, Shape C only | Shape B only | |||||||||||

| (Round) LPGJ LPGG LPG LPGB LPGR LPGS LPGD LPGC | (Diamond) LPDGJ LPDGG LPDG LPDGB LPDGR LPDGS LPDGC | A B C | 6 | −0.004 −0.012 | 6.50 to 12.00 | 2.0 to 40.0 (12.0) | Shape A R ≥ P/2 Shape C R ≤ P/2 | Shape B G ≤ P | 6 to 12 | M3 | 98 | 3 |

| 6T | M2.6 | — | ||||||||||

| 8 | −0.005 −0.014 | 9.00 to 15.00 | 2.0 to 40.0 (15.0) | 8 to 16 | M4 | 225 | 3.5 | |||||

| 10 | 11.00 to 20.00 | 3.0 to 50.0 (20.0) | 10 (12)Up to 20 | M5 | 461 | 4 | ||||||

| 10T | 6 (12)Up to 16 | M4 | 225 | |||||||||

| 12 | −0.006 −0.017 | 13.00 to 20.00 | 3.0 to 50.0 (20.0) | 12 to 24 | M5 | 461 | 5 | |||||

| 12T | 8 (12)Up to 18 | M4 | 225 | |||||||||

| 16 | 17.00 to 25.00 | 5.0 to 50.0 (20.0) | 16 to 32 | M8 | 1911 | 7 | ||||||

| 16T | 10 (14)Up to 24 | M6 | 784 | |||||||||

| 20 | −0.007 −0.020 | 21.00 to 35.00 | 5.0 to 50.0 (20.0) | 20 to 40 | M8 | 1911 | 9 | |||||

| 20T | 12 (18)Up to 30 | M6 | 784 | |||||||||

[ ! ]B, L dimensions in () are applicable to Diamond Shape. [!] Holes may go through.

| Part Number | P 0.1 mm Increments | B 0.1 mm Increments | R 1 mm Increments | G 1 mm Increments | ||

| Type | Tip Shape | M | ||||

| Shape A, Shape C only | Shape B only | |||||

| LPCJ LPCG LPC LPCB LPCR LPCS LPCD LPCC | A B C | 3 | 6.0 to 10.0 | 10.0 to 25.0 | Shape A R ≥ P/2 Shape C R ≤ P/2 | Shape B G ≤ P |

| 4 | 7.0 to 12.0 | 11.0 to 25.0 | ||||

| 5 | 8.0 to 16.0 | 13.0 to 30.0 | ||||

| 6 | 9.0 to 20.0 | 15.0 to 40.0 | ||||

| 8 | 11.0 to 20.0 | 19.0 to 50.0 | ||||

| 10 | 14.0 to 20.0 | 23.0 to 50.0 | ||||

| 12 | 18.0 to 25.0 | 28.0 to 60.0 | ||||

| 16 | 22.0 to 30.0 | 35.0 to 60.0 | ||||

| 20 | 26.0 to 30.0 | 44.0 to 60.0 | ||||

* The tightening torque (ref. value) for hardened products is strength class 8.8. Not applicable when using locking materials or lock washers.

Alterations

| Alterations Code | Alteration Details | Application Conditions | Ordering Example |

| SC | Adds Wrench Flats | SC = 1 mm Increments [ ! ] For Round Type: P-3 ≤ SC ≤ P-1, SC ≥ D [ ! ] For Straight Type: M + 3 ≤ SC ≤ P-1 [ ! ] When B ≤ 11, adds wrench flats on the tip | LPCA6-P10.0-B25.0-R6-SC9 |

| LAC | Adds a wrench hole (⌀3.5) | ø3.5 Hole Machining [ ! ] Applicable when B ≥ 10, P ≥ 8 | LPCA6-P10.0-B25.0-R6-LAC |

| LTE | Adds a wrench hole (⌀2.5) | ø2.5 Hole Machining [ ! ] Applicable when B ≥ 8, 7 ≤ P ≤ 15 | LPCA6-P10.0-B25.0-R6-LTE |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| LPCA3-P[6-10/0.1]-B[10-25/0.1]-R[2-500/1] |

| LPCA4-P[7-12/0.1]-B[11-25/0.1]-R[2-500/1] |

| LPCA5-P[8-16/0.1]-B[13-30/0.1]-R[3-500/1] |

| LPCA6-P[9-20/0.1]-B[15-40/0.1]-R[3-500/1] |

| LPCA8-P[11-20/0.1]-B[19-50/0.1]-R[4-500/1] |

| LPCA10-P[14-20/0.1]-B[23-50/0.1]-R[5-500/1] |

| LPCA12-P[18-25/0.1]-B[28-60/0.1]-R[6-500/1] |

| LPCA16-P[22-30/0.1]-B[35-60/0.1]-R[8-500/1] |

| LPCA20-P[26-30/0.1]-B[44-60/0.1]-R[10-500/1] |

| LPCB3-P[6-10/0.1]-B[10-25/0.1]-G[1-10/1] |

| LPCB4-P[7-12/0.1]-B[11-25/0.1]-G[1-12/1] |

| LPCB5-P[8-16/0.1]-B[13-30/0.1]-G[1-16/1] |

| LPCB6-P[9-20/0.1]-B[15-40/0.1]-G[1-20/1] |

| LPCB8-P[11-20/0.1]-B[19-50/0.1]-G[1-20/1] |

| LPCB10-P[14-20/0.1]-B[23-50/0.1]-G[1-20/1] |

| LPCB12-P[18-25/0.1]-B[28-60/0.1]-G[1-25/1] |

| LPCB16-P[22-30/0.1]-B[35-60/0.1]-G[1-30/1] |

| LPCB20-P[26-30/0.1]-B[44-60/0.1]-G[1-30/1] |

| LPCBA3-P[6-10/0.1]-B[10-25/0.1]-R[2-500/1] |

| LPCBA4-P[7-12/0.1]-B[11-25/0.1]-R[2-500/1] |

| LPCBA5-P[8-16/0.1]-B[13-35/0.1]-R[3-500/1] |

| LPCBA6-P[9-20/0.1]-B[15-40/0.1]-R[3-500/1] |

| LPCBA8-P[11-20/0.1]-B[19-50/0.1]-R[4-500/1] |

| LPCBA10-P[14-20/0.1]-B[23-50/0.1]-R[5-500/1] |

| LPCBA12-P[18-25/0.1]-B[28-60/0.1]-R[6-500/1] |

| LPCBA16-P[22-30/0.1]-B[35-60/0.1]-R[8-500/1] |

| LPCBA20-P[26-30/0.1]-B[44-60/0.1]-R[10-500/1] |

| LPCBB3-P[6-10/0.1]-B[10-25/0.1]-G[1-10/1] |

| LPCBB4-P[7-12/0.1]-B[11-25/0.1]-G[1-12/1] |

| LPCBB5-P[8-16/0.1]-B[13-30/0.1]-G[1-16/1] |

| LPCBB6-P[9-20/0.1]-B[15-40/0.1]-G[1-20/1] |

| LPCBB8-P[11-20/0.1]-B[19-50/0.1]-G[1-20/1] |

| LPCBB10-P[14-20/0.1]-B[23-50/0.1]-G[1-20/1] |

| LPCBB12-P[18-25/0.1]-B[28-60/0.1]-G[1-25/1] |

| LPCBB16-P[22-30/0.1]-B[35-60/0.1]-G[1-30/1] |

| LPCBB20-P[26-30/0.1]-B[44-60/0.1]-G[1-30/1] |

| LPCBC3-P[6-10/0.1]-B[10-25/0.1]-R[1-5/1] |

| LPCBC4-P[7-12/0.1]-B[11-25/0.1]-R[1-6/1] |

| LPCBC5-P[8-16/0.1]-B[13-35/0.1]-R[1-8/1] |

| LPCBC6-P[9-20/0.1]-B[15-40/0.1]-R[1-10/1] |

| LPCBC8-P[11-20/0.1]-B[19-50/0.1]-R[1-10/1] |

| LPCBC10-P[14-20/0.1]-B[23-50/0.1]-R[1-10/1] |

| LPCBC12-P[18-25/0.1]-B[28-60/0.1]-R[1-12/1] |

| LPCBC16-P[22-30/0.1]-B[35-60/0.1]-R[1-15/1] |

| LPCBC20-P[26-30/0.1]-B[44-60/0.1]-R[1-15/1] |

| LPCC3-P[6-10/0.1]-B[10-25/0.1]-R[1-5/1] |

| LPCC4-P[7-12/0.1]-B[11-25/0.1]-R[1-6/1] |

| LPCC5-P[8-16/0.1]-B[13-30/0.1]-R[1-8/1] |

| LPCC6-P[9-20/0.1]-B[15-40/0.1]-R[1-10/1] |

| LPCC8-P[11-20/0.1]-B[19-50/0.1]-R[1-10/1] |

| LPCC10-P[14-20/0.1]-B[23-50/0.1]-R[1-10/1] |

| LPCC12-P[18-25/0.1]-B[28-60/0.1]-R[1-12/1] |

| LPCC16-P[22-30/0.1]-B[35-60/0.1]-R[1-15/1] |

| LPCC20-P[26-30/0.1]-B[44-60/0.1]-R[1-15/1] |

| LPCCA3-P[6-10/0.1]-B[10-25/0.1]-R[2-500/1] |

| LPCCA4-P[7-12/0.1]-B[11-25/0.1]-R[2-500/1] |

| LPCCA5-P[8-16/0.1]-B[13-35/0.1]-R[3-500/1] |

| LPCCA6-P[9-20/0.1]-B[15-40/0.1]-R[3-500/1] |

| LPCCA8-P[11-20/0.1]-B[19-50/0.1]-R[4-500/1] |

| LPCCA10-P[14-20/0.1]-B[23-50/0.1]-R[5-500/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | RoHS | Basic Shape | Insertion Guide Tip Shape | Insertion Guide Tip Type | Surface Treatment | Heat Treatment | Material | Locating Side Outer Dia. P (Ø) (mm) | Mounting Side Outer Dia. D (mm) | Mounting Side Tolerance | Screw Dia. M (mm) | Mounting Section Length L (mm) | G (mm) | Length of Locating Side B (mm) | R (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 6 ~ 10 | - | - | 3 | - | - | 10 ~ 25 | 2 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 7 ~ 12 | - | - | 4 | - | - | 11 ~ 25 | 2 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 8 ~ 16 | - | - | 5 | - | - | 13 ~ 30 | 3 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 9 ~ 20 | - | - | 6 | - | - | 15 ~ 40 | 3 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 11 ~ 20 | - | - | 8 | - | - | 19 ~ 50 | 4 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 14 ~ 20 | - | - | 10 | - | - | 23 ~ 50 | 5 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 18 ~ 25 | - | - | 12 | - | - | 28 ~ 60 | 6 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 22 ~ 30 | - | - | 16 | - | - | 35 ~ 60 | 8 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 26 ~ 30 | - | - | 20 | - | - | 44 ~ 60 | 10 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 6 ~ 10 | - | - | 3 | - | 1 ~ 10 | 10 ~ 25 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 7 ~ 12 | - | - | 4 | - | 1 ~ 12 | 11 ~ 25 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 8 ~ 16 | - | - | 5 | - | 1 ~ 16 | 13 ~ 30 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 9 ~ 20 | - | - | 6 | - | 1 ~ 20 | 15 ~ 40 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 11 ~ 20 | - | - | 8 | - | 1 ~ 20 | 19 ~ 50 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 14 ~ 20 | - | - | 10 | - | 1 ~ 20 | 23 ~ 50 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 18 ~ 25 | - | - | 12 | - | 1 ~ 25 | 28 ~ 60 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 22 ~ 30 | - | - | 16 | - | 1 ~ 30 | 35 ~ 60 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 26 ~ 30 | - | - | 20 | - | 1 ~ 30 | 44 ~ 60 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 6 ~ 10 | - | - | 3 | - | - | 10 ~ 25 | 2 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 7 ~ 12 | - | - | 4 | - | - | 11 ~ 25 | 2 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 8 ~ 16 | - | - | 5 | - | - | 13 ~ 35 | 3 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 9 ~ 20 | - | - | 6 | - | - | 15 ~ 40 | 3 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 11 ~ 20 | - | - | 8 | - | - | 19 ~ 50 | 4 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 14 ~ 20 | - | - | 10 | - | - | 23 ~ 50 | 5 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 18 ~ 25 | - | - | 12 | - | - | 28 ~ 60 | 6 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 22 ~ 30 | - | - | 16 | - | - | 35 ~ 60 | 8 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 26 ~ 30 | - | - | 20 | - | - | 44 ~ 60 | 10 ~ 500 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 6 ~ 10 | - | - | 3 | - | 1 ~ 10 | 10 ~ 25 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 7 ~ 12 | - | - | 4 | - | 1 ~ 12 | 11 ~ 25 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 8 ~ 16 | - | - | 5 | - | 1 ~ 16 | 13 ~ 30 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 9 ~ 20 | - | - | 6 | - | 1 ~ 20 | 15 ~ 40 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 11 ~ 20 | - | - | 8 | - | 1 ~ 20 | 19 ~ 50 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 14 ~ 20 | - | - | 10 | - | 1 ~ 20 | 23 ~ 50 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 18 ~ 25 | - | - | 12 | - | 1 ~ 25 | 28 ~ 60 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 22 ~ 30 | - | - | 16 | - | 1 ~ 30 | 35 ~ 60 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Tapered | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 26 ~ 30 | - | - | 20 | - | 1 ~ 30 | 44 ~ 60 | - | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 6 ~ 10 | - | - | 3 | - | - | 10 ~ 25 | 1 ~ 5 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 7 ~ 12 | - | - | 4 | - | - | 11 ~ 25 | 1 ~ 6 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 8 ~ 16 | - | - | 5 | - | - | 13 ~ 35 | 1 ~ 8 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 9 ~ 20 | - | - | 6 | - | - | 15 ~ 40 | 1 ~ 10 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 11 ~ 20 | - | - | 8 | - | - | 19 ~ 50 | 1 ~ 10 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 14 ~ 20 | - | - | 10 | - | - | 23 ~ 50 | 1 ~ 10 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 18 ~ 25 | - | - | 12 | - | - | 28 ~ 60 | 1 ~ 12 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 22 ~ 30 | - | - | 16 | - | - | 35 ~ 60 | 1 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Black Oxide | Dip Quenching | [Steel] S45C Equivalent | 26 ~ 30 | - | - | 20 | - | - | 44 ~ 60 | 1 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 6 ~ 10 | - | - | 3 | - | - | 10 ~ 25 | 1 ~ 5 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 7 ~ 12 | - | - | 4 | - | - | 11 ~ 25 | 1 ~ 6 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 8 ~ 16 | - | - | 5 | - | - | 13 ~ 30 | 1 ~ 8 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 9 ~ 20 | - | - | 6 | - | - | 15 ~ 40 | 1 ~ 10 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 11 ~ 20 | - | - | 8 | - | - | 19 ~ 50 | 1 ~ 10 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 14 ~ 20 | - | - | 10 | - | - | 23 ~ 50 | 1 ~ 10 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 18 ~ 25 | - | - | 12 | - | - | 28 ~ 60 | 1 ~ 12 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 22 ~ 30 | - | - | 16 | - | - | 35 ~ 60 | 1 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | Straight | Round | Taper R | Not Provided | Dip Quenching | [Steel] S45C Equivalent | 26 ~ 30 | - | - | 20 | - | - | 44 ~ 60 | 1 ~ 15 | ||

- | 1 Piece(s) | 3 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Stainless Steel] SUS440C or Equivalent | 6 ~ 10 | - | - | 3 | - | - | 10 ~ 25 | 2 ~ 500 | ||

- | 1 Piece(s) | 3 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Stainless Steel] SUS440C or Equivalent | 7 ~ 12 | - | - | 4 | - | - | 11 ~ 25 | 2 ~ 500 | ||

- | 1 Piece(s) | 3 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Stainless Steel] SUS440C or Equivalent | 8 ~ 16 | - | - | 5 | - | - | 13 ~ 35 | 3 ~ 500 | ||

- | 1 Piece(s) | 3 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Stainless Steel] SUS440C or Equivalent | 9 ~ 20 | - | - | 6 | - | - | 15 ~ 40 | 3 ~ 500 | ||

- | 1 Piece(s) | 3 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Stainless Steel] SUS440C or Equivalent | 11 ~ 20 | - | - | 8 | - | - | 19 ~ 50 | 4 ~ 500 | ||

- | 1 Piece(s) | 3 Day(s) | 10 | Straight | Round | R | Not Provided | Dip Quenching | [Stainless Steel] SUS440C or Equivalent | 14 ~ 20 | - | - | 10 | - | - | 23 ~ 50 | 5 ~ 500 |

| Part Number |

|---|

Loading...Tải…

Basic InformationThông tin cơ bản

| Insertion Guide Specifications | Not Provided | Mounting Side Shape | Tapped | Locating Side O.D. Tolerance | 0/-0.01 |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy