(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 23/2 to 6:00 (ICT) 24/2/2025. We apologize for the inconvenience.

- Thể lệ và Giải thưởng cuộc thi "Thiết kế máy Tự động hóa 2025" do MISUMI Việt Nam tổ chức. Xem chi tiết.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more.

Chamfering / Centering Tools(Tool Material Type:Carbide Page4)

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentatio

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentation on the work material to avoid misalignment of the drill bit tip. Their materials include alloy carbide, powdered high-speed steel, cobalt high-speed steel and high-speed steel. Countersinking and chamfering cutters are capable of chamfering after drilling holes. Chamfering cutters with a hole on the tip allow for smooth cutting discharge on soft work materials such as copper and aluminum. Center drills have a 90° tip angle and they can be used for positioning and chamfering at the same time.

Search by specifying the lower class categoryTìm kiếm bằng cách chỉ định danh mục lớp thấp hơn

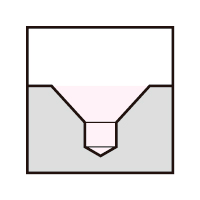

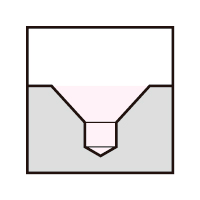

Centering/Countersink

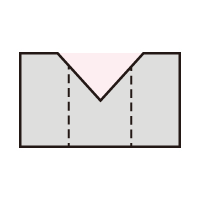

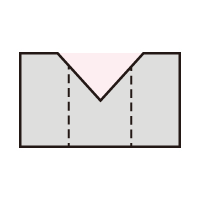

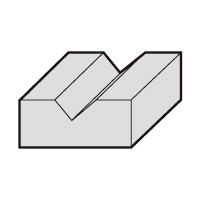

Centering/Countersink Chamfer, V-Grooves

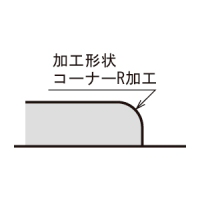

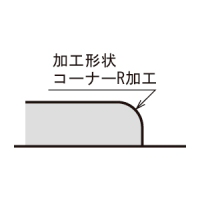

Chamfer, V-Grooves Inner R

Inner R Replaceable Blade Type Chamfering Tools/Tips/Blades

Replaceable Blade Type Chamfering Tools/Tips/Blades

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

173 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

Carbide Center Drill A Type 90°

DYC

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - - - - - Available / NA TiAlN / Non-Coated - Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Counter Sink 1-Flute & 90°-TiN

DYC

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 10 ~ 30 - - - - - Available TiN - From: 971,877 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Counterbore Straight Shank

DYC

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 6.5 ~ 31 - - - - - - - - From: 1,009,194 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide 2-Flute 90°Center Ring End Mill

DYC

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 - - - - - - - - From: 976,578 VND Days to Ship: Số ngày giao hàng: 7 Day(s)  7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

Carbide Solid Countersink 3-Flute C-3MC (NF15)

TAIYO-TOOL

[Applications]・ Hole chamfer[Single-edged / doubled-edged]・ Single-Edged[Tool material type]・ Carbide[Coating Y/N]・ N/A[Coating type]・ Uncoated[Number of flutes]・ 3-flute

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 6.3 ~ 25 60 ~ 120 Hole Chamfer - Single blade - NA Non-Coated - From: 4,837,295 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CoroMill Plura - General Purpose Chamfering End Mill, Cylindrical Shank / Weldon Shank

SANDVIK

High performance end mill with high versatility[Features]·One end mill for all work materials·Improved machine operating rate·Minimize tool inventory·Safe and predictable tool life·High flexibility and optimized tooling

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 6 ~ 12 90° Chamfering/Horizontal general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Single blade NA Available Other - From: 2,185,571 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

FX-MG-CS X 90 Hole Chamfering, 3-Flute Countersink, FX Coating Carbide 90° Series

OSG

High-speed cutting is possible compared to conventional products, and a wide range of processing such as deburring and chamfering can be performed, resulting in a beautiful finished surface. High-speed steel series and carbide series are available.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 3.8 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[◎] / Cast Iron[○] / Aluminum[○] / Copper[◎] / Graphite[○] / Resin[○] Single blade NA Available TiAlN - From: 5,483,191 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WXL-Coated Chamfering Cutter Negative Type Regular W-HSCT-N

OSG

[Features]・ Unique 3-flute specification suppresses chattering during machining and realizes high efficiency and high feed machining・ 40° twist and wide gullet combine sharpness and finished surface are achieved at a high level.・ The return and burr are drastically reduced・ Excellent cutting chip discharge

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - 90° Chamfering/Horizontal general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] Single blade NA Available - - From: 2,640,916 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Crystal Center Drill ZH330-TiN

RYOCO SEIKI

[Features]・ TiN coating is versatile and highly reliable coating・ The surface hardness is HV2,000 to 2,200, the heat-resistant temperature is around 500°C and the friction coefficient is 0.4

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.8 60 × 120 Centering (Positioning) - Double-edged NA Available TiN - From: 2,154,493 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WXL-Coated Chamfering Cutter Positive Type Regular W-HSCT-P

OSG

[Features]・ Unique 3-flute specification suppresses chatter during machining and realizes high efficiency and high feed machining.・ 40° twist and wide gullet combine sharpness and finished surface are achieved at a high level.・ Returns and burrs are drastically reduced.・ Excellent cutting chip discharge.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - - general steel[○] / Stainless Steel[◎] / Aluminum[◎] / Titanium[◎] - - Available Other - From: 2,640,916 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WXL-Coated Chamfering Cutter Positive Type Long Shank WLS-HSCT-P

OSG

[Features]・ Unique 3-flute specification suppresses chatter during machining and realizes high efficiency and high feed machining.・ 40° twist and wide gullet combine sharpness and finished surface are achieved at a high level.・ Returns and burrs are drastically reduced.・ Excellent cutting chip discharge.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - - general steel[○] / Stainless Steel[◎] / Aluminum[◎] / Titanium[◎] - - Available Other - From: 2,779,563 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

WXL-Coated Chamfering Cutter Negative Type Long Shank WLS-HSCT-N

OSG

[Features]· A unique 3-flute specification which helps prevent cracking during machining and which enables high-efficiency and high-feed machining. The 40° torsion and wide tip pockets enable both excellent cutting performance and high level surface finishing. Significantly reduces turning-back, or burring. Excellent chip discharge.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - - general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] - - Available Other - From: 2,779,563 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MUGEN Coating C Chamfer Cutter NSCV-M

NS TOOL

[Features]· It enables easy C chamfering.· Uses MUGEN coating that dramatically improves the durability.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 4 ~ 6 45° Chamfering/Horizontal general steel[○] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[◎] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] Single blade Available Available TiAlN - From: 2,077,788 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NS TOOL

[Features]· It allows easy chamfer edge machining.[Part Number: NSCV-4]cutting diameter (D) (mm): 4Blade length (mm): 2Shank diameter (d) (mm): 4Overall length (mm): 60Minimum order quantity: 1 pc.[Part Number: NSCV-6]cutting diameter (D) (mm): 6Blade length (mm): 3Shank diameter (d) (mm): 6Overall length (mm): 70Minimum order quantity: 1 pc.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 4 ~ 6 45° Chamfering/Horizontal Aluminum[◎] / Copper[◎] / Resin[◎] Single blade Available NA - - From: 2,448,000 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 60°

MAKOTOLOY

[Features]·1 pc. of V-cut end mill can be used for various purposes such as centering countersinking, inner chamfering, outer peripheral chamfering, side machining, V-groove, drilling, and is ideal for MC and NC machining·Since the cutting tip is close to the V edge, the residue on the bottom during V-groove machining is very few·Since it is based on a carbide end mill with a right blade and a right twist of 30°, the sharpness is one of the best and the discharge of cutting chips is also good·Since the ultra-fine carbide alloy is used as the carbide material, it has a lifespan approx. 10 times longer than that of HSS end mill. Furthermore, the V-cut end mill coating series has a long lifespan and increases cutting speed to shorten machining time・ Standard type

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,168,698 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 120°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.· Standard type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,168,698 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 60°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material.· Long tool life, improved cutting speed and reduced machining time.· Standard type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 2,906,958 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 90°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material.· Long tool life, improved cutting speed and reduced machining time.· Standard type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 2,906,958 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 120°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material.· Long tool life, improved cutting speed and reduced machining time.· Standard type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 2,906,958 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 60°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.· Long type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,601,146 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 90°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.· Long type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,601,146 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 120°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material, ensuring a long tool life.· Long type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,601,146 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Coated Series AMVL 60°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material.· Long tool life, improved cutting speed and reduced machining time.· Long type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 3,109,123 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Carbide End Mills, Long Type, Coated Series AMVL 90°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material.· Long tool life, improved cutting speed and reduced machining time.· Long type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 3,109,123 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide V Cut End Mill Long Type Coated Series AMVL 120°

MAKOTOLOY

[Features]· A single V-cut end mill that can be used for various purposes. Ideal for MC and NC machining.· The blade tip is close to a V-edge so there is minimum residue in the bottom part during V-grooving.· Based on a right-blade, clockwise-turning 30° type carbide end mill, ensuring optimum sharpness and good cutting chip discharge.· An ultra-fine particle carbide alloy is used for the carbide material.· Long tool life, improved cutting speed and reduced machining time.· Long type.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 20 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 3,109,123 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Small Diameter Carbide End Mills Non-Coating Series MVS 60°

MAKOTOLOY

[Features]· A small but high quality end mill that can also be used with high precision machining technology.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 0.9 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,370,248 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Small Diameter Carbide End Mills Non-Coating Series MVS 90°

MAKOTOLOY

[Features]· A small but high quality end mill that can also be used with high precision machining technology.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 0.9 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,370,248 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Small Diameter Carbide End Mills Non-Coating Series MVS 120°

MAKOTOLOY

[Features]· A small but high quality end mill that can also be used with high precision machining technology.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 0.9 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 2,370,248 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Small Diameter Carbide End Mills Coated Series AMVS 60°

MAKOTOLOY

[Features]· A small but high quality end mill that can also be used with high precision machining technology.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 0.9 60 Hole Chamfer / Chamfering/Horizontal general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 2,752,725 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Small Diameter Carbide End Mills Coated Series AMVS 90°

MAKOTOLOY

[Features]· A small but high quality end mill that can also be used with high precision machining technology.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 0.9 90 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 2,752,725 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V-Cut Small Diameter Carbide End Mills Coated Series AMVS 120°

MAKOTOLOY

[Features]· A small but high quality end mill that can also be used with high precision machining technology.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 0.9 120 Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 2,752,725 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V Spot Carbide Drill, Standard Type, TiN Coat, 90°

MAKOTOLOY

[Features]· Higher positioning precision than normal twist drills thanks to the small chisel edge.· Made using carefully selected carbides with a TiN coating, ensuring a long tool life.· The type with a 90° tip angle is capable of performing centering and chamfering simultaneously.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 25 90 Centering (Positioning) / Hole Chamfer general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiN - From: 2,607,406 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V Spot Carbide Drill, Standard Type, TiN Coat, 120°

MAKOTOLOY

[Features]· Higher positioning precision than normal twist drills thanks to the small chisel edge.· Made using carefully selected carbides with a TiN coating, ensuring a long tool life.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 25 120 Centering (Positioning) / Hole Chamfer general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiN - From: 2,607,406 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V Spot Carbide Drill, Long Type, TiN Coat, 90°

MAKOTOLOY

[Features]· Higher positioning precision than normal twist drills thanks to the small chisel edge.· Made using carefully selected carbides with a TiN coating, ensuring a long tool life.· The type with a 90° tip angle is capable of performing centering and chamfering simultaneously.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 25 90 Centering (Positioning) / Hole Chamfer general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiN - From: 3,362,911 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

V Spot Carbide Drill, Long Type, TiN Coat, 120°

MAKOTOLOY

[Features]· Higher positioning precision than normal twist drills thanks to the small chisel edge.· Made using carefully selected carbides with a TiN coating, ensuring a long tool life.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 25 120 Centering (Positioning) / Hole Chamfer general steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiN - From: 3,362,911 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Chamfering Cutter, Carbide, Uramen-Maru (Standard Type) C-BMC-V

THE CUT

[Features]· No need to turn over the work material. (Also removes through-hole burrs)· Both sides can be chamfered with the one cutter tool.· Ultra-fine particle carbide with TiAlN coating for a longer tool life.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 2.8 ~ 12 90° Hole Chamfer / Drilling / Other general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - Available TiAlN - From: 4,179,611 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Point Set Drill, Carbide C-NC-PSD

THE CUT

[Features]· Allows for machining at higher speeds and a significantly longer tool life than with a high speed steel (TiAlN) point set drill.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 3 ~ 10 90 Hole Chamfer general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Single blade - NA - - From: 926,571 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Dedicated Insert For Double Face Cutter, MT-SDM/H

THE CUT

Dedicated insert MT-SDM/H for THE CUT replaceable insert double-face chamfer tool.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide - - Hole Chamfer general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] - - Available / NA TiAlN - From: 278,774 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Tool Material Type |

| Tool Diameter (D)(mm) |

| Tip angle (θ) |

| Application |

| work material |

| Single blade, two blades |

| Peripheral Blade Y/N |

| Coating Y/N |

| Coating Type |

| R Size (R)(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | DYC | DYC | DYC | DYC | TAIYO-TOOL | SANDVIK | OSG | OSG | RYOCO SEIKI | OSG | OSG | OSG | NS TOOL | NS TOOL | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | MAKOTOLOY | THE CUT | THE CUT | THE CUT |

| Product SeriesDòng sản phẩm | CoroMill Plura - General Purpose Chamfering End Mill, Cylindrical Shank / Weldon Shank | FX-MG-CS X 90 Hole Chamfering, 3-Flute Countersink, FX Coating Carbide 90° Series | WXL-Coated Chamfering Cutter Positive Type Long Shank WLS-HSCT-P | WXL-Coated Chamfering Cutter Negative Type Long Shank WLS-HSCT-N | V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 60° | V-Cut Carbide End Mills, Standard Type, Non-Coating Series MVS 120° | V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 60° | V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 90° | V-Cut Carbide End Mills, Standard Type, Coated Series AMVS 120° | V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 60° | V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 90° | V-Cut Carbide End Mills, Long Type, Non-Coating Series MVL 120° | V-Cut Small Diameter Carbide End Mills Non-Coating Series MVS 60° | V-Cut Small Diameter Carbide End Mills Non-Coating Series MVS 90° | V-Cut Small Diameter Carbide End Mills Non-Coating Series MVS 120° | V-Cut Small Diameter Carbide End Mills Coated Series AMVS 60° | V-Cut Small Diameter Carbide End Mills Coated Series AMVS 90° | V-Cut Small Diameter Carbide End Mills Coated Series AMVS 120° | Chamfering Cutter, Carbide, Uramen-Maru (Standard Type) C-BMC-V | |||||||||||||||||||

| CADCAD | ||||||||||||||||||||||||||||||||||||||

| From | 971,877 VND | 1,009,194 VND | 976,578 VND | 4,837,295 VND | 2,185,571 VND | 5,483,191 VND | 2,640,916 VND | 2,154,493 VND | 2,640,916 VND | 2,779,563 VND | 2,779,563 VND | 2,077,788 VND | 2,448,000 VND | 2,168,698 VND | 2,168,698 VND | 2,906,958 VND | 2,906,958 VND | 2,906,958 VND | 2,601,146 VND | 2,601,146 VND | 2,601,146 VND | 3,109,123 VND | 3,109,123 VND | 3,109,123 VND | 2,370,248 VND | 2,370,248 VND | 2,370,248 VND | 2,752,725 VND | 2,752,725 VND | 2,752,725 VND | 2,607,406 VND | 2,607,406 VND | 3,362,911 VND | 3,362,911 VND | 4,179,611 VND | 926,571 VND | 278,774 VND | |

| Days to ShipSố ngày giao hàng | 7 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 7 Day(s) | 7 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 8 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 7 Day(s) or more | 9 Day(s) or more |

| Tool Material Type | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide |

| Tool Diameter (D)(mm) | - | 10 ~ 30 | 6.5 ~ 31 | 3 ~ 20 | 6.3 ~ 25 | 6 ~ 12 | 1 ~ 3.8 | - | 0.8 | - | - | - | 4 ~ 6 | 4 ~ 6 | 1 ~ 20 | 1 ~ 20 | 1 ~ 20 | 1 ~ 20 | 1 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 3 ~ 20 | 0.3 ~ 0.9 | 0.3 ~ 0.9 | 0.3 ~ 0.9 | 0.3 ~ 0.9 | 0.3 ~ 0.9 | 0.3 ~ 0.9 | 3 ~ 25 | 3 ~ 25 | 3 ~ 25 | 3 ~ 25 | 2.8 ~ 12 | 3 ~ 10 | - |

| Tip angle (θ) | - | - | - | - | 60 ~ 120 | 90° | 90 | 90° | 60 × 120 | - | - | - | 45° | 45° | 60 | 120 | 60 | 90 | 120 | 60 | 90 | 120 | 60 | 90 | 120 | 60 | 90 | 120 | 60 | 90 | 120 | 90 | 120 | 90 | 120 | 90° | 90 | - |

| Application | - | - | - | - | Hole Chamfer | Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove | Chamfering/Horizontal | Centering (Positioning) | - | - | - | Chamfering/Horizontal | Chamfering/Horizontal | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Hole Chamfer / Chamfering/Horizontal | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer / Chamfering/Horizontal / V Groove / Drilling | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Hole Chamfer / Drilling / Other | Hole Chamfer | Hole Chamfer |

| work material | - | - | - | - | - | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[◎] / Cast Iron[○] / Aluminum[○] / Copper[◎] / Graphite[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] | - | general steel[○] / Stainless Steel[◎] / Aluminum[◎] / Titanium[◎] | general steel[○] / Stainless Steel[◎] / Aluminum[◎] / Titanium[◎] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] | general steel[○] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[◎] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] | Aluminum[◎] / Copper[◎] / Resin[◎] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] |

| Single blade, two blades | - | - | - | - | Single blade | Single blade | Single blade | Single blade | Double-edged | - | - | - | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | Single blade | - |

| Peripheral Blade Y/N | - | - | - | - | - | NA | NA | NA | NA | - | - | - | Available | Available | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Coating Y/N | Available / NA | Available | - | - | NA | Available | Available | Available | Available | Available | Available | Available | Available | NA | NA | NA | Available | Available | Available | NA | NA | NA | Available | Available | Available | NA | NA | NA | Available | Available | Available | Available | Available | Available | Available | Available | NA | Available / NA |

| Coating Type | TiAlN / Non-Coated | TiN | - | - | Non-Coated | Other | TiAlN | - | TiN | Other | Other | Other | TiAlN | - | - | - | TiAlN | TiAlN | TiAlN | - | - | - | TiAlN | TiAlN | TiAlN | - | - | - | TiAlN | TiAlN | TiAlN | TiN | TiN | TiN | TiN | TiAlN | - | TiAlN |

| R Size (R)(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...Tải…

- << PrevTrước

- 1

- 2

- 3

- 4

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Tool Material Type

- High-speed steel

- Cobalt HSS

- Powder high-speed steel

- Carbide

- Vanadium High Speed Steel

- High-vanadium High Speed Steel

- SKH55

-

Tool Diameter (D)(mm)

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.35

- 0.4

- 0.45

- 0.45~2.1

- 0.45~2.7

- 0.5

- 0.55

- 0.6

- 0.65

- 0.65~2.1

- 0.65~2.7

- 0.7

- 0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1–6

- 1/8

- 1/16

- 1/32

- 1/64

- 1.1

- 1.2

- 1.25

- 1.3

- 1.4

- 1.5

- 1.6

- 1.7

- 1.8

- 1.9

- 2.

- 2

- 2–10

- 2~13

- 2.1

- 2.2

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

- 3

- 3~14

- 3 to 15

- 3/16

- 3/32

- 3/64

- 3.1

- 3.15

- 3.2

- 3.3

- 3.4

- 3.5

- 3.6

- 3.8

- 4

- 4.2

- 4.3

- 4.4

- 4.5

- 4.6

- 4.8

- 5

- 5/16

- 5/32

- 5/64

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.6

- 5.8

- 6

- 6.2

- 6.3

- 6.3,8.3,10.4,12.4,16.5,20.5

- 6.30/8.30/10.40/12.40/16.50/20.50

- 6.3/8.3/10.4/12.4/16.5/20.5

- 6.35

- 6.4

- 6.5

- 6.6

- 6.8

- 7

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 8

- 8.2

- 8.3

- 8.4

- 8.5

- 8.8

- 9

- 9.1

- 9.4

- 9.5

- 9.52

- 10

- 10.1

- 10.2

- 10.3

- 10.4

- 10.5

- 10.8

- 11

- 11.1

- 11.2

- 11.4

- 11.5

- 11.88

- 12

- 12.1

- 12.3

- 12.4

- 12.5

- 12.7

- 13

- 13.4

- 13.5

- 14

- 14.2

- 14.4

- 14.5

- 14.6

- 14.8

- 15

- 15.1

- 15.2

- 15.4

- 15.5

- 15.6

- 15.87

- 16

- 16.15

- 16.3

- 16.5

- 16.5,20.5,25.0,37.0

- 17

- 17.1

- 17.5

- 17.7

- 18

- 18.2

- 18.5

- 18.6

- 19

- 19.05

- 19.5

- 20

- 20.5

- 21

- 21.77

- 22

- 22.3

- 22.5

- 23

- 23.4

- 23.5

- 24

- 24.5

- 25

- 25.0(+0.3)

- Max: 25, Min: 4.2

- 25.20

- 25.3

- 25.5

- 26

- 26.5

- 26.6

- 27

- 27.5

- 28

- 28.5

- 29

- 29.9

- 30

- Max: 30, Min: 4

- 30.20

- 30.5

- 31

- Max: 31, Min: 10

- 31.5

- 31.7

- 31.9

- 32

- 32.6

- 32.7

- 33.1

- 33.3

- 34

- 34.1

- 34.8

- 34.9

- 35

- 35.4

- 35.5

- 35.9

- 36

- 36.9

- 37

- 37.1

- 37.9

- 38

- 39

- 39.83

- 40

- Max: 41, Min: 20

- 42

- 43

- 45

- 45.6

- 46

- 47

- 48

- 49

- 49.85~134.6

- 50

- 50.7

- 51

- 52

- 52.8

- 53

- 53.6

- 53.91

- 54

- 54.3

- 55

- 56

- 56.8

- 57.0

- 57.9

- 58

- 58.2

- 60

- 61.4

- 62

- 62.2

- 63

- 64

- 64.6

- 65

- 66

- 67.4

- 67.94

- 69.2

- 69.8

- 70

- 71.8

- 72

- 73.3

- 74

- 75

- 76

- 80

- 90

- 95

- 100

-

Tip angle (θ)

- 0–90

- 5~85

- 5~85°

- 15

- 20

- 25

- 30

- 35

- 40

- 45

- 45°

- 50

- 55

- 60

- 60°

- 60˚

- 60 × 120

- 65

- 70

- 75

- 80

- 90

- 90°

- Center Hole Angle: 90°

- Cutter Tip Angle: 100°

- 118

- 120

- 120°

- 120˚

- 125°

- 130

- 135

- 145+90

- 150

-

Application

-

Centering (Positioning)

-

Hole Chamfer

-

Chamfering/Horizontal

-

V Groove

-

Round Chamfer

-

Engraved

-

Drilling

-

Other

-

Centering (Positioning)

-

work material

- general steel

- Quenched and tempered steel

- high hardness steel

- Stainless Steel

- Cast Iron

- Aluminum

- Titanium

- Copper

- Graphite

- Resin

-

Single blade, two blades

-

Peripheral Blade Y/N

-

Coating Y/N

-

Coating Type

-

R Size (R)(mm)

- 0.1

- 0.15

- 0.2

- 0.25

- 0.3

- 0.35

- 0.4

- 0.45

- 0.5

- R0.5

- 0.5/1/1.5/2

- 0.5 to 4

- 0.5~5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- R0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1RM

- 1RY

- R1

- 1/2/3/4

- 1–3

- 1–5

- 1.05

- 1.1

- 1.15

- 1.2

- 1.25

- R1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- R1.5

- 1.55

- 1.6

- 1.65

- 1.7

- 1.75

- 1.8

- 1.85

- 1.9

- 1.95

- 2

- 2RM

- 2RY

- R2

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- 2.3

- 2.35

- 2.4

- 2.45

- 2.5

- R2.5

- 2.6

- 2.7

- 2.75

- 2.8

- 2.9

- 3

- 3RM

- 3RY

- R3

- 3.25

- 3.5

- R3.5

- 3.75

- 4

- 4RM

- 4RY

- R4

- 4.25

- 4.5

- R4.5

- 4.75

- 5

- 5RM

- R5

- 5–10

- 5.25

- 5.5

- 5.75

- 6

- R6

- 6.25

- 6.5

- 6.75

- 7

- R7

- 7.25

- 7.5

- 7.75

- 8

- R8

- 8.25

- 8.5

- 8.75

- 9

- R9

- 9.5

- 10

- R10

- 10.5

- 11

- 11.5

- 12

- R12

- 12.5

- R12.5

- 13

- 13.5

- 14

- 14.5

- 15

- R15

- 15.5

- 16

- R16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 20.5

- 21

- 21.5

- 22

- 22.5

- 23

- 23.5

- 24

- 24.5

- 25

- 25.5

- 26

- 26.5

- 27

- 27.5

- 28

- 28.5

- 29

- 29.5

- 30

- XRM

- XRY

Related Categories to Chamfering / Centering ToolsDanh mục liên quan đến Chamfering / Centering Tools

-

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy