(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

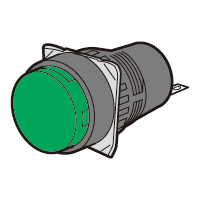

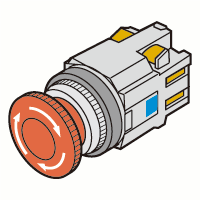

IDEC Push Buttons(Shape:Other)

IDEC offers products Push Buttons specified by Shape Other from Electrical & Controls product category. There are a total of 1 items. Parts and equipment for controlling machines and electrical systems. Controllers and power supplies. IDEC products are available to order through MISUMI online 24/7. Free shipping, no minimum order.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

IDEC

SS terminals are equipped with finger protection structure, enabling safety and time-saving capabilities.

Mounting Hole Shape Type Push button operation Button color Contact Configuration Terminal shape Guard included Dimension depth(mm) Protection function (environmentally resistant) Representative Standard Dimension width(mm) Dimension vertical(mm) Ø22 Other - Momentary / Alternate Green / Black 1a / 1b / 2a Screw terminal NA 68.4 Available CE / UL / TUV / CCC / CSA 29.4 41.4 From: 342,251 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| From |

| Days to ShipSố ngày giao hàng |

| Mounting Hole |

| Shape |

| Type |

| Push button operation |

| Button color |

| Contact Configuration |

| Terminal shape |

| Guard included |

| Dimension depth(mm) |

| Protection function (environmentally resistant) |

| Representative Standard |

| Dimension width(mm) |

| Dimension vertical(mm) |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | IDEC |

| Product SeriesDòng sản phẩm | |

| From | 342,251 VND- |

| Days to ShipSố ngày giao hàng | 6 Day(s) or more |

| Mounting Hole | Ø22 |

| Shape | Other |

| Type | - |

| Push button operation | Momentary / Alternate |

| Button color | Green / Black |

| Contact Configuration | 1a / 1b / 2a |

| Terminal shape | Screw terminal |

| Guard included | NA |

| Dimension depth(mm) | 68.4 |

| Protection function (environmentally resistant) | Available |

| Representative Standard | CE / UL / TUV / CCC / CSA |

| Dimension width(mm) | 29.4 |

| Dimension vertical(mm) | 41.4 |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Mounting Hole

- Ø6

- Ø8

- Ø10

- Ø12

- Ø16

- Ø22

- Ø25

- Ø30

- Square Hole

- Other

-

Shape

-

Round

-

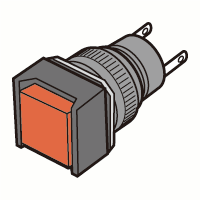

Square

-

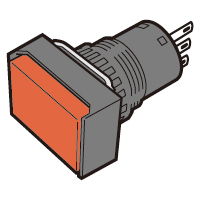

Elongated

-

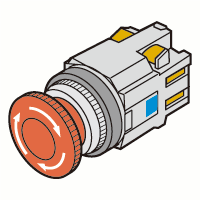

Mushroom shape

-

Other

-

Round

-

Type

- Illuminated emergency stop

- Non-illumination type emergency stop

- Illumination push-button

- Non-illumination type push-button

- Other

- Selector

-

Push button operation

- Momentary

- Alternate

- Push to lock/turn to reset

- Other

-

Button color

- Red

- Blue

- Green

- Yellow

- White

- Black

- Amber

- Other

- Orange

- Pure yellow

- Pure White

-

Contact Configuration

- 1a

- 1b

- 2a

- 2b

- 3a

- 3b

- 1c

- 2c

- 1a2b

- 4a

-

Terminal shape

- Solder terminal

- Screw terminal

- PC terminal

- Insertion Terminal

- Solder terminal/tab terminal

- Other

-

Guard included

- Available

- NA

-

Dimension depth(mm)

-

Protection function (environmentally resistant)

- Available

- NA

-

Representative Standard

- PSE

- CE

- UL

- CUL

- TUV

- CCC

- CSA

-

Dimension width(mm)

-

Dimension vertical(mm)

Related Categories to Push ButtonsDanh mục liên quan đến Push Buttons

FAQ Push Buttons

- Question: What are the characteristics of push buttons used in electrical circuits?

- Answer: Push buttons used in electrical circuits should be small, compact, easy to install, and have good fire resistance. They should also be able to withstand moisture and other environmental conditions well, depending on the environment in which the machine is installed. In addition, they should have a fast response, which can be considered from the material used in the production of the contacts of the push button. The push button should also be manufactured according to international industrial standards.

- Question: How do push button switches integrate with industrial control systems?

- Answer: In industrial control systems, push buttons act as crucial input interfaces, bridging human commands to automated processes, for example:

1.Direct control: Wired directly to controllers, button presses trigger immediate actions – starting motors, stopping conveyors, or initiating emergency shutdowns.

2.Logic integration: Buttons feed data into PLCs, influencing complex control sequences based on their programmed functions within the larger system. - Question: What distinguishes a push-pull switch from a standard push button?

- Answer:

This table summarizes the key differences between push switches and push-pull switches

Feature Push Button Switch Push-Pull Switch Functionality Momentary action: Makes or breaks the circuit temporarily when pressed. Dual action: Can be operated by both pushing and pulling, often serving two different functions. Typical Usage Used for applications requiring a momentary connection, such as turning on a location of the base while the button is held down. Commonly used when a switch needs to control two functions, with pushing and pulling corresponding to different actions (e.g., on/off). Activation Type Activated by pressing the button or switch. Activated by both pushing and pulling the actuator. Return to Rest State Returns to the original state (off) when the button is released. May have different actions for pushing and pulling, and returns to the original state accordingly. Examples Doorbell buttons,momentary control switches. Headlight switches in automobiles, power control in some lighting fixtures - Question: What factors should be considered when selecting push buttons for machinery?

- Answer: 1. Application Requirements: Identify the specific function the push button that appropriate for the machine for example momentary or maintained.

2. Environmental Conditions: Consider the environmental conditions in which the machinery operates (e.g., indoor, outdoor, wet, dusty).

3. Voltage and Current Ratings: Ensure that the push button is rated for the voltage and current levels of the machinery it will control.

4. Size and Mounting Options: Select push buttons of an appropriate size for the machinery control panel. Consider the mounting options

5. Compliance with Standards: Check whether the push buttons comply with relevant industry standards and regulations, especially those related to safety.

6. Maintenance and Replacement: Evaluate the ease of maintenance and replacement of push buttons. Quick and straightforward replacement can minimize downtime. - Question: How do waterproof push button switches benefit industrial applications?

- Answer: Waterproof push buttons for machinery in industrial settings are offering numerous benefits:

1. Safety : They shield sensitive electronics from spills, splashes, and cleaning, preventing short circuits and safeguarding operators.

2. Durable : These buttons have long lifespan and reducing maintenance peroid.

3. Reliable : Industrial processes demand unwavering control. Waterproof buttons minimize moisture-induced malfunctions, ensuring smooth operation in production.

4. Hygiene : In critical environments like food and pharma indrustrials, waterproof buttons let you clean with confidence, preventing contamination and upholding strict hygiene standards.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy