(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

SMC Solenoid Valves(Switching Type:3-Position Exhaust Center Page3)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

93 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

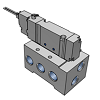

ATEX Directive 5-Port Solenoid Valve, 56-VQC2000 Series, ATEX Category 3

SMC

[What is ATEX Directive?]Since July 1, 2003, it has been mandatory within the EU to comply with the ATEX Directive for equipment used in potentially explosive atmospheres.■CE mark and ATEXThe ATEX Directive is now part of the CE mark, which incorporates the traditional European explosion-proof standard.■Purpose of ATEX DirectiveThe main purposes of ATEX are:・ Prevention of electrostatic charge・ Ignition prevention of sparks caused by friction, impact, and abrasion・ Ignition prevention due to temperature rise due to the same as above・ The responsibility lies with the manufacturer・ Certification by zone/category■Zone/CategoryIn ATEX, the objects to be applied are classified into categories for each dangerous place (zone).・ Zone 0: Category 1Possibility of explosive atmosphere (Zone): Continuous or long time > 1,000 hours/year・ Zone 1: Category 2Possibility of explosive atmosphere (Zone): occasionally 10 to 1,000 hours/year・ Zone 2: Category 3Possibility of explosive atmosphere (Zone): Less likely, short time < 10 hours/year

Number of Ports Application Switching Type Voltage Number of Solenoids Mounting Orientation Pipe Port Type Specifications Status at Power Off Plumbing Thread Nominal Plumbing Applicable Cylinder Dia.(Ø) Type Driving Type Connecting Tube Diameter Pressure Rating(MPa) Seal Type CV Value Pilot Air Supply 5-Port Valve Unit for Manifold Mounting 3-Position Exhaust Center DC24V Double Manifold Base - Drip-Proof / Lubrication Free Self-Recovery (Spring Return) - Sub-Base Plumbing - Solenoid Valves Pilot Type Spool - 0.2 to 0.7 Soft Seal 0.49 Internal Days to Ship: Số ngày giao hàng: Quote  Quote

Quote

-

You can add up to 6 items per a category to the compare list.

ATEX Directive 5-Port Solenoid Valve, 56-VQC4000 Series, ATEX Category 3

SMC

[What is ATEX Directive?]Since July 1, 2003, it has been mandatory within the EU to comply with the ATEX Directive for equipment used in potentially explosive atmospheres.■CE mark and ATEXThe ATEX Directive is now part of the CE mark, which incorporates the traditional European explosion-proof standard.■Purpose of ATEX DirectiveThe main purposes of ATEX are:・ Prevention of electrostatic charge・ Ignition prevention of sparks caused by friction, impact, and abrasion・ Ignition prevention due to temperature rise due to the same as above・ The responsibility lies with the manufacturer・ Certification by zone/category■Zone/CategoryIn ATEX, the objects to be applied are classified into categories for each dangerous place (zone).・ Zone 0: Category 1Possibility of explosive atmosphere (Zone): Continuous or long time > 1,000 hours/year・ Zone 1: Category 2Possibility of explosive atmosphere (Zone): occasionally 10 to 1,000 hours/year・ Zone 2: Category 3Possibility of explosive atmosphere (Zone): Less likely, short time < 10 hours/year

Number of Ports Application Switching Type Voltage Number of Solenoids Mounting Orientation Pipe Port Type Specifications Status at Power Off Plumbing Thread Nominal Plumbing Applicable Cylinder Dia.(Ø) Type Driving Type Connecting Tube Diameter Pressure Rating(MPa) Seal Type CV Value Pilot Air Supply 5-Port Valve Unit for Manifold Mounting 3-Position Exhaust Center DC24V Double Manifold Base - Drip-Proof / Lubrication Free Self-Recovery (Spring Return) - Sub-Base Plumbing 200 or less Solenoid Valves Pilot Type Spool - 0.15 to 1 / 0.2 to 1 Standard / Soft Seal 1.5 ~ 1.9 Internal Days to Ship: Số ngày giao hàng: Quote  Quote

Quote

-

You can add up to 6 items per a category to the compare list.

5-Port Solenoid Valve, Base Mounted, Clean, 10-VQ2000

SMC

[10-Series, Clean Series]Suitable for clean environmentPrevents dust generation in the cleanroom

Number of Ports Application Switching Type Voltage Number of Solenoids Mounting Orientation Pipe Port Type Specifications Status at Power Off Plumbing Thread Nominal Plumbing Applicable Cylinder Dia.(Ø) Type Driving Type Connecting Tube Diameter Pressure Rating(MPa) Seal Type CV Value Pilot Air Supply 5-Port Valve Unit for Manifold Mounting 3-Position Exhaust Center DC24V Double Manifold Base - Lubrication Free / Cleanroom Self-Recovery (Spring Return) - Sub-Base Plumbing - Solenoid Valves Pilot Type Spool - 0.1 to 0.7 / 0.2 to 0.7 Standard / Soft Seal 0.46 ~ 0.49 Internal Days to Ship: Số ngày giao hàng: Quote  Quote

Quote

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Number of Ports |

| Application |

| Switching Type |

| Voltage |

| Number of Solenoids |

| Mounting Orientation |

| Pipe Port Type |

| Specifications |

| Status at Power Off |

| Plumbing Thread Nominal |

| Plumbing |

| Applicable Cylinder Dia.(Ø) |

| Type |

| Driving Type |

| Connecting Tube Diameter |

| Pressure Rating(MPa) |

| Seal Type |

| CV Value |

| Pilot Air Supply |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | SMC | SMC | SMC |

| Product SeriesDòng sản phẩm | ATEX Directive 5-Port Solenoid Valve, 56-VQC2000 Series, ATEX Category 3 | ATEX Directive 5-Port Solenoid Valve, 56-VQC4000 Series, ATEX Category 3 | |

| CADCAD | |||

| From | - | - | - |

| Days to ShipSố ngày giao hàng | Quote | Quote | Quote |

| Number of Ports | 5-Port Valve | 5-Port Valve | 5-Port Valve |

| Application | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting |

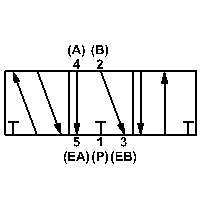

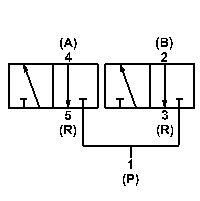

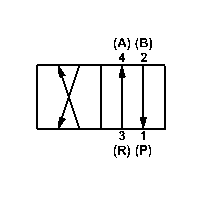

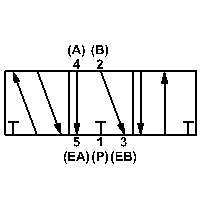

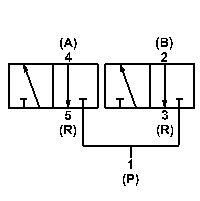

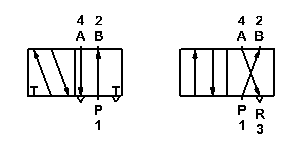

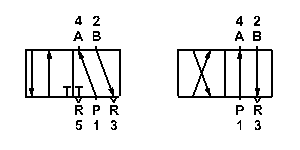

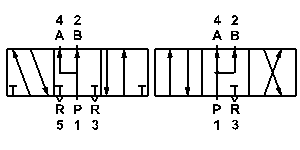

| Switching Type | 3-Position Exhaust Center | 3-Position Exhaust Center | 3-Position Exhaust Center |

| Voltage | DC24V | DC24V | DC24V |

| Number of Solenoids | Double | Double | Double |

| Mounting Orientation | Manifold Base | Manifold Base | Manifold Base |

| Pipe Port Type | - | - | - |

| Specifications | Drip-Proof / Lubrication Free | Drip-Proof / Lubrication Free | Lubrication Free / Cleanroom |

| Status at Power Off | Self-Recovery (Spring Return) | Self-Recovery (Spring Return) | Self-Recovery (Spring Return) |

| Plumbing Thread Nominal | - | - | - |

| Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing |

| Applicable Cylinder Dia.(Ø) | - | 200 or less | - |

| Type | Solenoid Valves | Solenoid Valves | Solenoid Valves |

| Driving Type | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool |

| Connecting Tube Diameter | - | - | - |

| Pressure Rating(MPa) | 0.2 to 0.7 | 0.15 to 1 / 0.2 to 1 | 0.1 to 0.7 / 0.2 to 0.7 |

| Seal Type | Soft Seal | Standard / Soft Seal | Standard / Soft Seal |

| CV Value | 0.49 | 1.5 ~ 1.9 | 0.46 ~ 0.49 |

| Pilot Air Supply | Internal | Internal | Internal |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Number of Ports

-

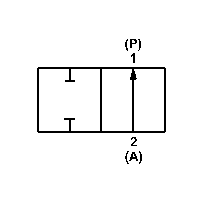

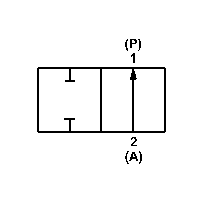

2-Port Valve

-

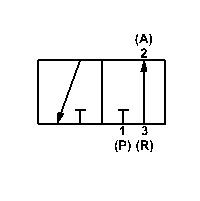

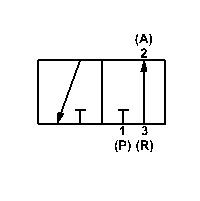

3-Port Valve

-

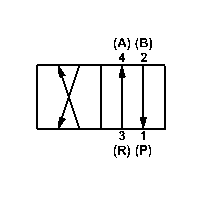

4-Port Valve

-

5-Port Valve

-

Dual 3-Port Valve

-

2-Port Valve

-

Application

- Single Use

- Manifolds

- Unit for Manifold Mounting

-

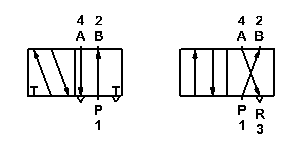

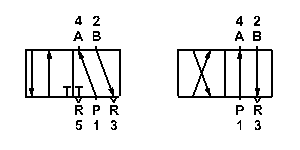

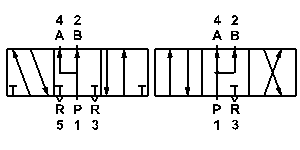

Switching Type

-

2-Position Normally Open

-

2-Position Normally Closed

-

2-Position Exhaust

-

2-Position Pressure

-

3-Position Closed Center

-

3-Position Exhaust Center

-

3-Position Pressure Center

-

Others

-

2-Position Normally Open

-

Voltage

-

Number of Solenoids

- Single

- Double

-

Mounting Orientation

-

Direct

-

Manifold Base

- Rail

-

Direct

-

Pipe Port Type

-

Specifications

- Standard

- High Frequency

- Low Vacuum Compatible

- Explosion Proof

- Drip-Proof

- Ozone Compatible

- Lubrication Free

- No Copper, fluoropolymer Type Material

- Low Current

- Cleanroom

-

Status at Power Off

- Self-Retaining

- Self-Recovery (Spring Return)

- Self-Recovery (Pressure Differential Return)

-

Plumbing Thread Nominal

-

Plumbing

-

Applicable Cylinder Dia.(Ø)

-

Type

- Solenoid Valves

- Master Valve

- Base Only

- Related Components

-

Driving Type

-

Connecting Tube Diameter

-

Pressure Rating(MPa)

-

Seal Type

-

CV Value

-

Pilot Air Supply

Related Categories to Solenoid ValvesDanh mục liên quan đến Solenoid Valves

FAQ Solenoid Valves

- Question: How do solenoid valves work? How does a solenoid valve control flow?

- Answer: Solenoid valves are electromechanical devices used to control the flow of fluids or gases in a system. They work based on the principle of electromagnetism. The valve consists of a coil (solenoid) and a plunger inside it.

When an electric current passes through the coil, it creates a magnetic field, which attracts the plunger to move. This movement of the plunger opens or closes the valve's passage, allowing or blocking the flow of fluid or gas through the valve.

By controlling the electric current to the coil, we can control the position of the plunger and, consequently, regulate the flow of the fluid or gas passing through the valve. - Question: What are the different types of solenoid valves?

- Answer: There are several types of solenoid valves based on their design and applications. The main types include:

2-way solenoid valves: These have one inlet and one outlet and are used to start or stop the flow of fluid or gas.

3-way solenoid valves: These have one inlet and two outlets (or vice versa). They can divert the flow between two different paths or mix two different fluids.

4-way solenoid valves: These have two inlets and two outlets and are commonly used in applications like directional control of pneumatic cylinders.

Direct-acting solenoid valves: These valves use the force of the solenoid to directly open and close the valve.

Pilot-operated solenoid valves: These use a smaller solenoid to control the flow of a larger valve, allowing them to handle higher pressures and flow rates. - Question: What are the applications of solenoid valves?

- Answer: Solenoid valves are used in various applications across industries due to their ability to control fluid and gas flow efficiently. Some common applications include:

Controlling water flow in irrigation systems and plumbing fixtures.

Regulating air and gas flow in pneumatic systems and HVAC systems.

Automation and control of industrial processes in factory automation.

Medical equipment, such as in blood analyzers and dental instruments.

Dispensing and vending machines for liquids and gases.

Automotive applications, like fuel and air control in engines. - Question: How to select the right solenoid valve for my application?

- Answer: To select the right solenoid valve for your application, consider the following factors:

Valve Type: Choose the appropriate valve type (2-way, 3-way, etc.) based on your flow control requirements.

Fluid or Gas Compatibility: Ensure the solenoid valve is compatible with the fluid or gas used in your system.

Flow Rate and Pressure: Determine the required flow rate and operating pressure to select a valve that can handle the expected conditions.

Voltage and Power: Check the voltage and power supply available in your system to match it with the solenoid valve's requirements.

Environmental Conditions: Consider factors like temperature, humidity, and surrounding conditions to ensure the valve can withstand the environment.

Response Time: Evaluate the response time needed for your application, as it impacts the speed of valve operation.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy