(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Disc Springs(Inner Dia. d:5(4))

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

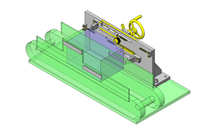

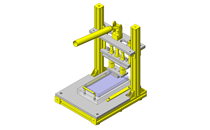

Disc Spring BD (Iwata Standard)

IWATA DENKO

[Features]· A spring for applying pressure. Eliminates bearing vibration and noise while also damping irregular rotations.· Helps to increase bearing life and markedly simplify design and space.

- Volume Discount

Outer Dia. D(Ø) Inner Dia. d(Ø) Applied Load Load P3 (at 0.75h)(N) Material Plate Thickness t(mm) Free Height Ho(mm) Load P1 (at 0.25h)(N) Total Deflection h(mm) Deflection δ Load P1 (at 0.50h)(N) 16 5(4) For Light Load - Spring Steel 0.25 0.55 - 0.3 - - From: 12,026 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| From |

| Days to ShipSố ngày giao hàng |

| Outer Dia. D(Ø) |

| Inner Dia. d(Ø) |

| Applied Load |

| Load P3 (at 0.75h)(N) |

| Material |

| Plate Thickness t(mm) |

| Free Height Ho(mm) |

| Load P1 (at 0.25h)(N) |

| Total Deflection h(mm) |

| Deflection δ |

| Load P1 (at 0.50h)(N) |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | IWATA DENKO |

| Product SeriesDòng sản phẩm | |

| From | 12,026 VND |

| Days to ShipSố ngày giao hàng | 7 Day(s) or more |

| Outer Dia. D(Ø) | 16 |

| Inner Dia. d(Ø) | 5(4) |

| Applied Load | For Light Load |

| Load P3 (at 0.75h)(N) | - |

| Material | Spring Steel |

| Plate Thickness t(mm) | 0.25 |

| Free Height Ho(mm) | 0.55 |

| Load P1 (at 0.25h)(N) | - |

| Total Deflection h(mm) | 0.3 |

| Deflection δ | - |

| Load P1 (at 0.50h)(N) | - |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Outer Dia. D(Ø)

-

Inner Dia. d(Ø)

-

Applied Load

- For Heavy Load

- For Light Load

-

Load P3 (at 0.75h)(N)

- 1,109

- 1,180

- 1,315

- 1,322

- 1,380

- 1,476

- 1,590

- 1,600

- 1,664

- 1,681

- 1,810

- 1,870

- 2,278

- 2,474

- 2,542

- 3,174

- 3,290

- 3,370

- 3,680

- 3,770

- 4,130

- 4,146

- 4,490

- 4,522

- 5,110

- 5,460

- 5,657

- 6,410

- 6,697

- 8,040

- 10,409

- 13,400

- 61

- 102

- 107.8

- 133

- 136

- 179

- 186.2

- 205.9

- 209.86

- 232

- 234

- 239

- 245

- 256

- 264.6

- 274

- 282

- 294

- 316

- 323.6

- 333

- 358

- 360

- 372.4

- 373

- 411.9

- 459

- 495

- 509.6

- 568.8

- 572

- 588

- 614

- 630

- 637

- 648

- 657.1

- 666.4

- 691

- 715.4

- 751

- 766

- 769

- 774.2

- 794.3

- 812

- 896

- 921

- 929

- 931

- 981

- 1019.2

- 1020

- 1029.7

- 1040

- 1120

- 1127.8

- 1140

- 1146.6

- 1180

- 1274.9

- 1340

- 1372

- 1380

- 1520

- 1528.8

- 1550

- 1590

- 1720

- 1724.8

- 1734.6

- 1810

- 1870

- 1912.3

- 1931.9

- 1950

- 2352

- 2557.8

- 2626.4

- 2843.9

- 2922.4

- 3060

- 3157.74

- 3283

- 3290

- 3488.8

- 3680

- 3690

- 3770

- 3873.6

- 4018

- 4130

- 4282.6

- 4490

- 4540

- 4730

- 5110

- 5197.5

- 5460

- 5850.6

- 6000

- 6046.6

- 6487.6

- 6501.8

- 6928.6

- 7160

- 7260

- 7610

- 7680

- 7698.2

- 8040

- 9437.4

- 10231.2

- 10760.4

- 11300

- 11376

- 12500

- 12700

- 12700.8

- 13494.6

- 13900

- 15004

- 15200

- 16500

- 18482.8

- 18600

- 20545

- 22600

- 28253.4

- 30213.4

- 32800

- 33588

- 34500

- 34800

- 36300

- 37500

- 39356.8

- 39800

- 39900

- 42100

- 43178.8

- 43500

- 43757

- 43800

- 43900

- 47600

- 48100

- 51500

- 53300

- 55000

- 56400

- 76763.4

- 77322

- 81900

- 85975

- 93300

- 94700

- 96000

- 96900

- 111000

- 112984.2

- 117000

- 138000

- 154000

- 203000

- 229000

- 274000

-

Material

- S65~70C (Black Oxide)

- SUS304-CSP

- SUP-10

- Spring Steel

- Special Steel

-

Plate Thickness t(mm)

-

Free Height Ho(mm)

- 0.4

- 0.45

- 0.5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- 0.85

- 0.9

- 1

- 1.05

- 1.1

- 1.2

- 1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- 1.55

- 1.6

- 1.7

- 1.75

- 1.8

- 1.85

- 1.87

- 1.88

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- 2.3

- 2.45

- 2.5

- 2.6

- 2.65

- 2.7

- 2.75

- 2.8

- 3.05

- 3.1

- 3.15

- 3.2

- 3.25

- 3.3

- 3.4

- 3.5

- 3.6

- 3.8

- 4.1

- 4.2

- 4.25

- 4.3

- 4.41

- 4.5

- 4.65

- 4.9

- 5.1

- 5.3

- 5.6

- 6

- 6.3

- 6.7

- 7

- 7.75

- 8.2

- 8.5

- 8.6

- 8.9

- 9

- 9.3

- 9.4

- 9.6

- 10

- 10.3

- 10.4

- 10.5

- 10.6

- 10.8

- 11.1

- 11.2

- 11.5

- 12

- 12.2

- 12.8

- 13.5

- 13.6

- 13.8

- 14

- 16.2

- 19

- 19.6

-

Load P1 (at 0.25h)(N)

- 29.1

- 55

- 55.7

- 87.5

- 88.26

- 101

- 128

- 136

- 141

- 145

- 161

- 188

- 266

- 291

- 326

- 337

- 342

- 402

- 409

- 415

- 496

- 507

- 511

- 593

- 603

- 692

- 698

- 750

- 771

- 894

- 1300

- 1304.28

- 1360

- 1370

- 1520

- 1640

- 1730

- 1960

- 2030

- 2090

- 2320

- 2400

- 2890

- 3080

- 3160

- 3540

- 3870

- 4610

- 4790

- 4800

- 4820

- 5920

- 5980

- 6290

- 6390

- 8130

- 9580

- 12400

- 13300

- 15600

- 16200

- 16500

- 17500

- 17600

- 18300

- 18500

- 18900

- 21400

- 21600

- 22100

- 22300

- 33200

- 33500

- 33700

- 34800

- 41300

- 42000

- 49600

- 53900

- 54800

- 71700

- 89900

-

Total Deflection h(mm)

-

Deflection δ

- 0.75h (mm)

-

Load P1 (at 0.50h)(N)

- 48.4

- 103

- 155.93

- 164

- 170

- 230

- 238

- 252

- 258

- 280

- 345

- 459

- 522

- 582

- 605

- 620

- 690

- 749

- 797

- 844

- 886

- 948

- 952

- 1120

- 1210

- 1280

- 1340

- 1390

- 1430

- 2324.18

- 2440

- 2460

- 2540

- 2560

- 2640

- 3030

- 3070

- 3550

- 3740

- 3770

- 3820

- 4230

- 5380

- 5540

- 5660

- 5820

- 6240

- 8380

- 8660

- 9060

- 9110

- 10300

- 10500

- 11200

- 11400

- 15300

- 15600

- 23800

- 24800

- 25600

- 26400

- 27300

- 30200

- 30300

- 30900

- 31900

- 32500

- 33100

- 35800

- 36500

- 38700

- 39400

- 39900

- 60100

- 64300

- 65400

- 65500

- 65900

- 78300

- 79800

- 90500

- 95200

- 105000

- 139000

- 164000

Related Categories to Disc SpringsDanh mục liên quan đến Disc Springs

FAQ Disc Springs

- Question: What are disc springs used for?

- Answer: Disc spring washers are used to absorb the vibration and shock loads in bolt assemblies that are suitable for industries that use high-vibration machinery. It depends on how you put the disc spring washers on.

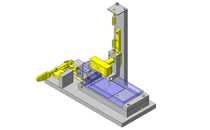

1. Parallel - When tightening the bolt and nut, The disc spring washer will help distribute the compression force equally from the bolt to the flange. Make good seals to prevent leakage.

2. Stacking - this method provides a spring constant and prevents deflecting force. Make it act like a shock absorber that helps to decrease the bolt's loose from vibration.

3. Combined This method combined the advantages of Parallel and Stacking together. - Question: What is the material of disc springs?

- Answer: Here are some common materials for disc springs or Belleville spring consist of

1. Carbon steel: Carbon steel is the most common material for disc springs. It is relatively inexpensive and easy to work with. However, carbon steel has a relatively low fatigue limit, so it is not suitable for applications where the spring will be subjected to a lot of repeated loading and unloading.

2. Stainless steel: Stainless steel is a more corrosion-resistant material than carbon steel. It is also more fatigue resistant, so it is suitable for applications where the spring will be subjected to a lot of repeated loading and unloading. However, stainless steel is more expensive than carbon steel.

3. Chrome vanadium steel: Chrome vanadium steel is a high-strength material that is often used in applications where the spring will be subjected to high loads. It is also more fatigue resistant than carbon steel or stainless steel. However, chrome vanadium steel is more expensive than these other materials.

4. Beryllium copper: Beryllium copper is a very strong and fatigue-resistant material. It is also corrosion-resistant and has a high spring rate. However, beryllium copper is a very expensive material. - Question: How do I choose a disc spring?

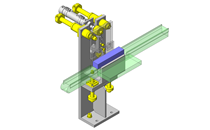

- Answer: 1. Choose a Disc Spring that has the right dimensions, which include the Outer diameter, Inner diameter, Thickness and Height.

2. Choose a Disc Spring that matches the temperature in the operation area - which has 4 ranges: normal temperature, >150°C, >300°C and >600°C.

3. Choose a Disc Spring that is resistant to chemicals and corrosion.

4. Choose a Disc Spring that is matched to the Load of the application. - Question: What is the difference between a wave washer and a disc spring?

- Answer: Wave washers and disc springs are both types of spring washers that are used to provide a preload in bolted assemblies. However, there are some key differences between the two types of washers.

• Wave washers are typically made from a single piece of metal that has been shaped into a wave pattern. The wave pattern creates a series of peaks and valleys that provide a progressive preload as the bolt is tightened. Wave washers are typically used in applications where a high preload is required, such as in heavy-duty machinery.

• Disc springs are typically made from a stack of thin discs that have been sandwiched together. The discs are shaped into a conical frustum, which creates a spring-like action when the bolt is tightened. Disc springs are typically used in applications where a repeatable preload is required, such as in pressure control valves, shock absorbers and clutches.

In general, wave washers are a good choice for applications where a high preload is required, while disc springs are a good choice for applications where a repeatable preload is required.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy