(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Scrap Retention Reverse Tapered Dies(Inside shape:Regular)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

5 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

Scrap Retention Full Length Reverse Taper Button Dies -Headed Type-

MISUMI

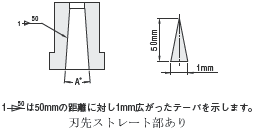

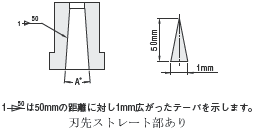

Button die surface treatment products are now available for the first time! Strengthen the cutting edge and inner surface! New surface treatment technology solves problems such as ``I want to extend the lifespan of button dies as well as punches'' and ``I'm going through trial and error in coating button dies.'' font color="red">"α Processing®"is the solution. [Characteristics of α Treatment®]・Achieve improved hardness without impairing toughness through nanocrystallization on the treated surface! ・Compared to conventional surface treatments, it can be strengthened by minimizing changes in the current dimensions, cutting edge shape, and groove shape to prevent scrap removal! ・By forming a micro-texture on the treated surface, the coefficient of friction is reducedImproved sliding properties! *What is a reverse taper button die to prevent scrap removal?What is a reverse taper button die to prevent scrap removal?By creating a minute taper from the cutting edge of the button die to the back, scraps can be reduced. This is a product that suppresses the rise. Effective for high tensile strength materials, etc., where the cutting waste shrinks during punching.

Shape Tip shape Inside shape Scrap retention Machining to prevent scrap clogging Material Headed type A / D / R / E / G Regular Reverse taper No SKH51 Equivalent Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Scrap Retention Full Length Reverse Taper Button Dies -Straight Type-

MISUMI

Button die surface treatment products are now available for the first time! Strengthen the cutting edge and inner surface! New surface treatment technology solves problems such as ``I want to extend the lifespan of button dies as well as punches'' and ``I'm going through trial and error in coating button dies.'' font color="red">"α Processing®"is the solution. [Characteristics of α Treatment®]・Achieve improved hardness without impairing toughness through nanocrystallization on the treated surface! ・Compared to conventional surface treatments, it can be strengthened by minimizing changes in the current dimensions, cutting edge shape, and groove shape to prevent scrap removal! ・By forming a micro-texture on the treated surface, the coefficient of friction is reducedImproved sliding properties! *What is a reverse taper button die to prevent scrap removal?What is a reverse taper button die to prevent scrap removal?By creating a minute taper from the cutting edge of the button die to the back, scraps can be reduced. This is a product that suppresses the rise. Effective for high tensile strength materials, etc., where the cutting waste shrinks during punching.

Shape Tip shape Inside shape Scrap retention Machining to prevent scrap clogging Material Straight A / D / R / E / G Regular Reverse taper No SKH51 Equivalent Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Scrap Retention Reverse Taper Button Dies Headed Type

MISUMI

*Added outer diameter size lineup. (Φ32~56)Button die surface treatment products are now available for the first time! Strengthen the cutting edge and inner surface! A new surface treatment technology solves problems such as ``I want to extend the lifespan of button dies as well as punches'' and ``I'm going through trial and error in coating button dies.'' font color="red">"α Processing®"is the solution. [Characteristics of α Treatment®]・Achieve improved hardness without compromising toughness through nanocrystallization on the treated surface! ・Compared to conventional surface treatments, it can be strengthened by minimizing changes in the current dimensions, cutting edge shape, and groove shape to prevent scrap build-up! ・By forming a micro-texture on the treated surface, the coefficient of friction is reducedImproved sliding properties! *What is a reverse taper button die to prevent scrap removal?What is a reverse taper button die to prevent scrap removal?By creating a minute taper from the cutting edge of the button die to the back, scraps can be reduced. This is a product that suppresses the rise. Effective for high tensile strength materials, etc., where the cutting waste shrinks during punching.

Shape Tip shape Inside shape Scrap retention Machining to prevent scrap clogging Material Headed type A / D / R / E / G Regular Reverse taper No SKD11 Equivalent / SKH51 Equivalent / Powdered high-speed steel Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Scrap Retention Reverse Taper Button Dies Straight Type

MISUMI

*Added outer diameter size lineup. (Φ32~56)Button die surface treatment products are now available for the first time! Strengthen the cutting edge and inner surface! A new surface treatment technology solves problems such as ``I want to extend the lifespan of button dies as well as punches'' and ``I'm going through trial and error in coating button dies.'' font color="red">"α Processing®"is the solution. [Characteristics of α Treatment®]・Achieve improved hardness without compromising toughness through nanocrystallization on the treated surface! ・Compared to conventional surface treatments, it can be strengthened by minimizing changes in the current dimensions, cutting edge shape, and groove shape to prevent scrap build-up! ・By forming a micro-texture on the treated surface, the coefficient of friction is reducedImproved sliding properties! *What is a reverse taper button die to prevent scrap removal?What is a reverse taper button die to prevent scrap removal?By creating a minute taper from the cutting edge of the button die to the back, scraps can be reduced. This is a product that suppresses the rise. Effective for high tensile strength materials, etc., where the cutting waste shrinks during punching.

Shape Tip shape Inside shape Scrap retention Machining to prevent scrap clogging Material Straight A / D / R / E / G Regular Reverse taper No SKD11 Equivalent / SKH51 Equivalent / Powdered high-speed steel Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Scrap Retention Reverse Angular Button Dies Dowel Slot Type

MISUMI

*Added outer diameter size lineup. (Φ32~56)Button die surface treatment products are now available for the first time! Strengthen the cutting edge and inner surface! A new surface treatment technology solves problems such as ``I want to extend the lifespan of button dies as well as punches'' and ``I'm going through trial and error in coating button dies.'' font color="red">"α Processing®"is the solution. [Characteristics of α Treatment®]・Achieve improved hardness without compromising toughness through nanocrystallization on the treated surface! ・Compared to conventional surface treatments, it can be strengthened by minimizing changes in the current dimensions, cutting edge shape, and groove shape to prevent scrap build-up! ・By forming a micro-texture on the treated surface, the coefficient of friction is reducedImproved sliding properties! *What is a reverse taper button die to prevent scrap removal?What is a reverse taper button die to prevent scrap removal?By creating a minute taper from the cutting edge of the button die to the back, scraps can be reduced. This is a product that suppresses the rise. Effective for high tensile strength materials, etc., where the cutting waste shrinks during punching.

Shape Tip shape Inside shape Scrap retention Machining to prevent scrap clogging Material Dowel fixing A / D / R / E / G Regular Reverse taper No SKD11 Equivalent Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Shape |

| Tip shape |

| Inside shape |

| Scrap retention |

| Machining to prevent scrap clogging |

| Material |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

| Product SeriesDòng sản phẩm | Scrap Retention Full Length Reverse Taper Button Dies -Headed Type- | Scrap Retention Full Length Reverse Taper Button Dies -Straight Type- | |||

| CADCAD |

|

|

|

|

|

| From | |||||

| Days to ShipSố ngày giao hàng | 9 Day(s) or more | 9 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more |

| Shape | Headed type | Straight | Headed type | Straight | Dowel fixing |

| Tip shape | A / D / R / E / G | A / D / R / E / G | A / D / R / E / G | A / D / R / E / G | A / D / R / E / G |

| Inside shape | Regular | Regular | Regular | Regular | Regular |

| Scrap retention | Reverse taper | Reverse taper | Reverse taper | Reverse taper | Reverse taper |

| Machining to prevent scrap clogging | No | No | No | No | No |

| Material | SKH51 Equivalent | SKH51 Equivalent | SKD11 Equivalent / SKH51 Equivalent / Powdered high-speed steel | SKD11 Equivalent / SKH51 Equivalent / Powdered high-speed steel | SKD11 Equivalent |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Shape

-

Headed type

-

Straight

-

Dowel fixing

-

Headed type

-

Tip shape

-

A

-

D

-

R

-

E

-

G

-

A

-

Inside shape

-

Regular

-

Angular

-

Regular

-

Scrap retention

- Reverse taper

-

Machining to prevent scrap clogging

- No

-

Material

- SKD11 Equivalent

- SKH51 Equivalent

- Powdered high-speed steel

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy